PDC Cutters for Mining

Features:

Good abrasion resistance; High impact resistance. Excellent heat resistance.

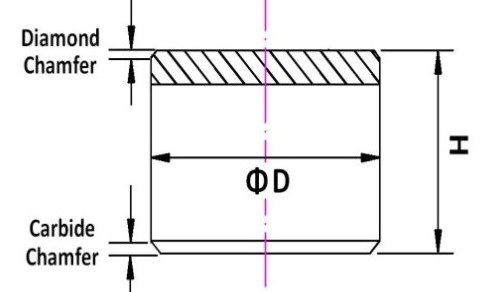

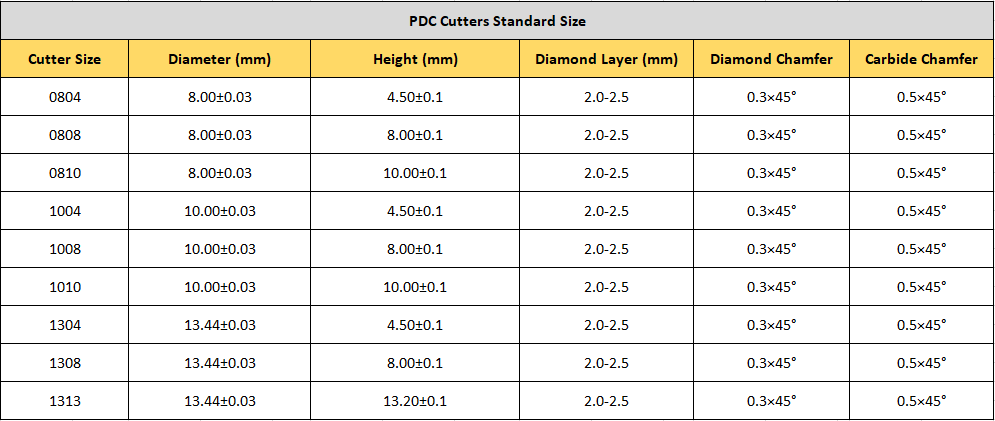

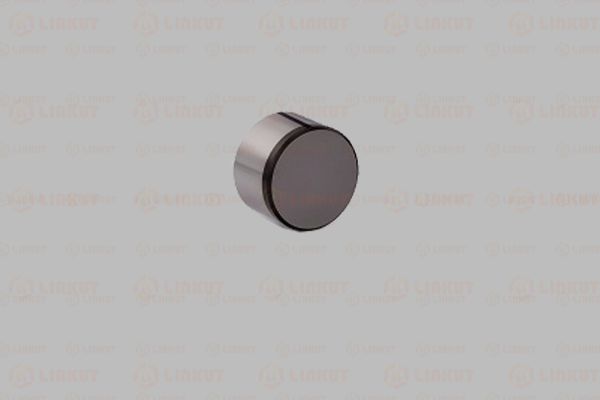

Polycrystalline diamond compact (PDC) are sintered by high-quality diamond micropowder and

carbide substrate under ultra-high temperature and high pressure conditions.

They have both hardness and wear resistance of diamond and high strength&impact toughness

of carbide. Our PDC insert cutters have a high wear ratio and impact resistance.

The diamond composite carefully choose the micron diamond powder and tungsten

carbide substrate materials, with consitent quality and longer tool life.

Advantages:

High hardness: the hardness of our PDC cutter insert can meet the high quality requirements of customers

through VTL vertical machine tool test;

Strong wear resistance: uses high quality polycrystalline diamond raw materials to ensure the wear

resistance meets customer requirements;

Lower friction factor;

High thermal conductivity;

Small expansion coefficient.

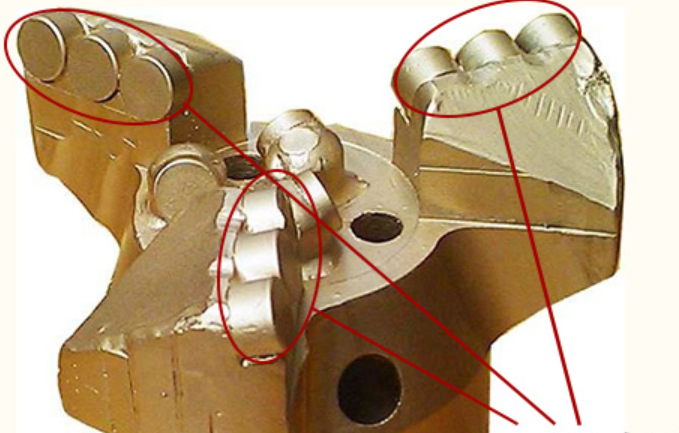

Used for oil and gas mining drills, water wells, mining mines, etc; can also be used for oil drill pipes,

reamer, and thrust bearings for oil and gas.

-

Spherical PDC Cutters

Details -

PDC Cutters for Mining

Details -

PDC Cutters for Geological Drilling

Details -

PDC Cutters for Oil&Gas

Details