Self-supported PCD Die Blanks

Features:

Good wear resistance; High hardness; Better heat resistance.

The pcd wire die drawing blank is a diamond fine powder sintered by ultra-high temperature and

ultra-high pressure process under the action of various metal (cobalt-containing) catalysts.

During the sintering process, high-strength diamond bonds are formed between the diamond

crystallite particles, and the diamond micropowder particles are strongly bonded together to form

polycrystalline diamond (PCD). The pcd die blanks produced by the method has high wear resistance,

hardness and thermal conductivity, and has good mechanical strength and toughness, and is suitable

for drawing non-ferrous metals such as copper, aluminum and nickel, stainless steel and various alloys wire.

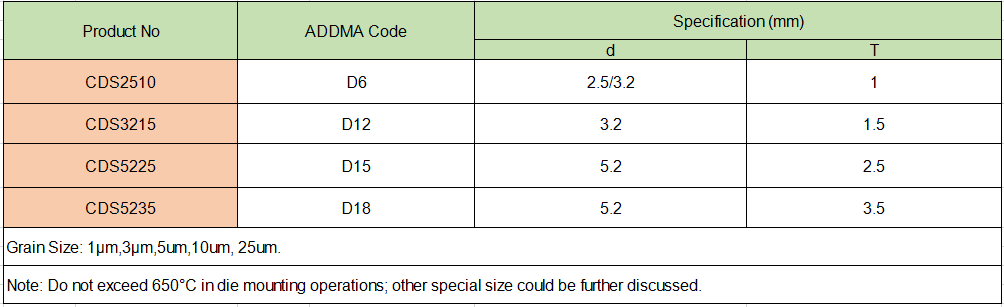

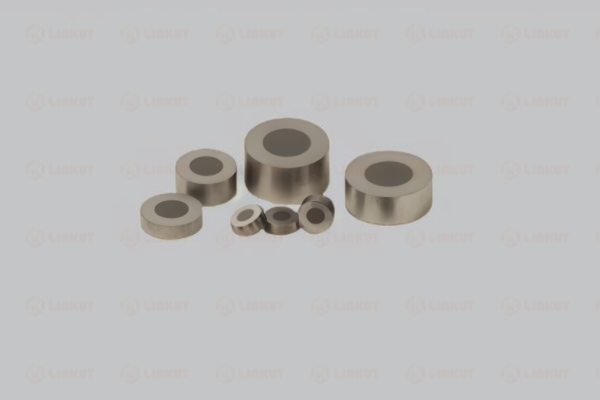

CDS Series: Cobalt bond Self-supported PCD Die Blanks

The Cobalt based drawing die blank without outer ring support is divided into hexagon and round

shape. These sizes of pcd die blanks are suitable for all types of wire drawing applications,

especially for wire drawing dies that consume a large amount of material.

Availabe Grain Size: 3um, 5um, 10um, 25um, 50um, etc.

Different choices of particle size can help customers increase mold life, improve wire finish, and

control size.

Diamond wire die is an important drawing tool for stainless steel wire and cable industry production.

For drawing copper wire, aluminum wire, tungsten wire, nickel wire, high carbon steel cord, and other alloy

wires.

Can be used for wet and dry drawing applications; from rod-size to fine-size.

Maximum recommend bearing diameter for “soft” non ferrous wire . “Hard” wire diameter normally should

not exceed 65% of this diameter.

-

Tungsten Carbide Supported PCD Die Blank

Details -

Conductive Silicon Bond PCD Die Blanks

Details -

Silicon Bond PCD Die Blanks

Details -

Self-supported PCD Die Blanks

Details