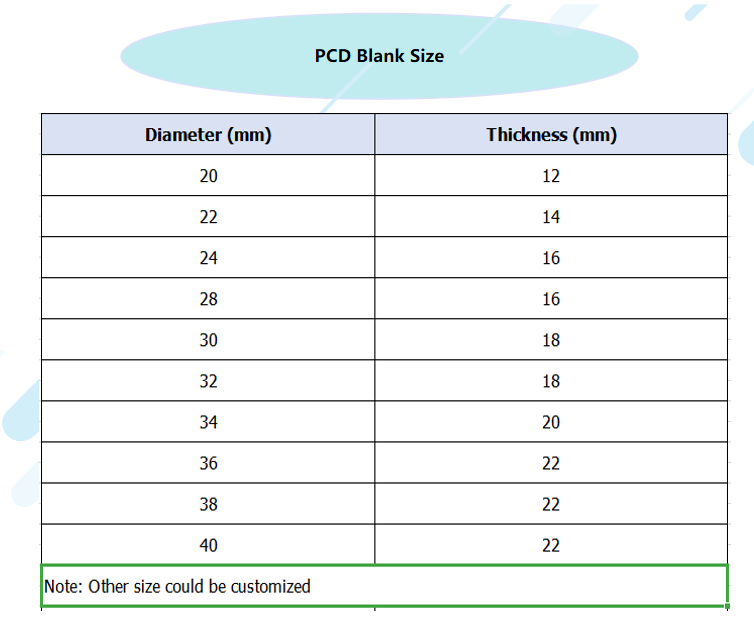

Conductive Silicon Bond PCD Die Blanks

Features:

Conductive;

High thermal stability and heat reistance;

High cost performance for big diameters.

Conductive Silicon-based thermally stable diamond polycrystalline diamond wire drawing die blanks use silicon as a binder

to form silicon carbide on the carbon atoms on the surface of silicon and diamond, connecting the diamond particles and

particles.

All products are manufactured with strict raw material control, scientific and reasonable proportioning design and stable

parameter control to ensure product quality.

SCB Series: Silicon Conductive High Thermal Stability

SCB Series: Silicon Conductive High Thermal Stability

The upgrade of STB series, which could adopts EDM cutting.

Products Features:

Good electrical conductivity, can be quickly cut with slow wire;

High temperature resistance, heat resistant temperature can reach 1100 ° C.

Excellent wear resistance, wear ratio is greater than 10 × 104.

Products Advantages (Compared with Co Based PCD Blanks):

Heat resistance is higher;

When processed by EDM, the processing speed is slightly faster;

Cost performance is much better;

The tool life is almost same for processing soft metal such as copper or aluminum;

The uniformity of the center and edge is much better.

SCB type diamond die blanks are mainly used for bunching, compacing, extrusion and stranding

die.

For drawing such as brass-plated wire, stainless wire, welding wire, tire cord, electrical wire, etc.

-

Silicon Bond PCD Die Blanks

Details -

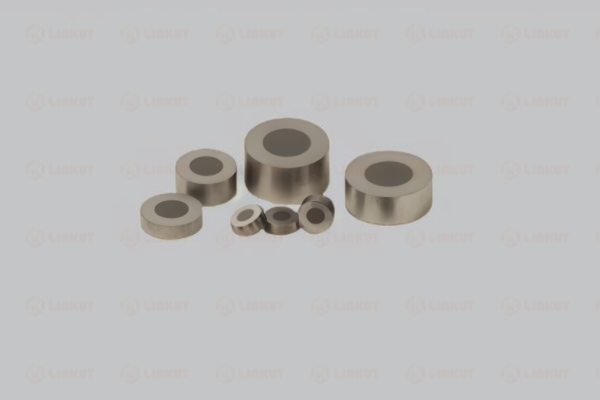

Self-supported PCD Die Blanks

Details -

Tungsten Carbide Supported PCD Die Blank

Details -

Conductive Silicon Bond PCD Die Blanks

Details