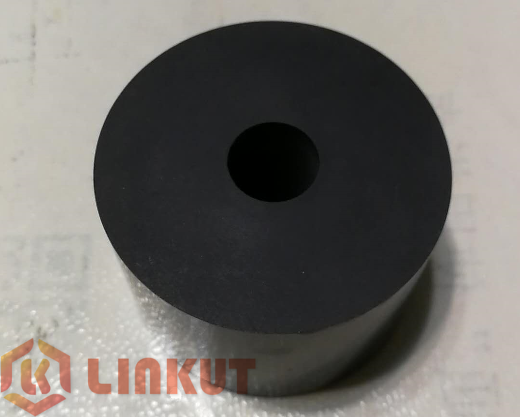

Long Tool Life PCD (polycrystalline Diamond ) Nozzle

Polycrystalline diamond, as the most hard and wear-resistant material in the world, is undoubtedly the best material for nozzle core, such as Versimax PCD.

The nozzle made of LINKUT EDM cuttable (conductive silicon bond) large-size polycrystalline diamond has obtained unprecedented high wear resistance.

According to the customers feedback for our PCD blanks, which has steady quality and long service life:

1) PCD service life is 10-20 times longer than that of boron carbide nozzle;

2) 100-200 times longer than that of cemented carbide (tungsten steel) nozzle;

3) More than 200 times that of alumina nozzle.

The carbide nozzle, boron carbide nozzle and polycrystalline diamond nozzle of the same specification with a 6 mm inner hole and a diameter of 20 × 35 mm were

selected for comparison. The high hardness metal surface was sandblasted with 24 mesh green silicon carbide sand:

1) Cemented carbide nozzle can be used for 8-10 working shifts;

2) Boron carbide nozzle can be used for 70-80 work shifts;

3) Polycrystalline diamond nozzle can be used for more than 1000 work shifts.

1 year change the nozzle one time will be ok, which could greatly save your production cost.

Previous Article:The PCD Cutter Inserts Application In High-end Matrix Bit

Next Article: How to Improve Machining Efficiency and Prolong PCBN Cutting Tool Life