The Machining characteristics of Nickel Hard Cast Iron

RNGN CBN Turning Inserts for Machining Nickel Hard Cast Iron

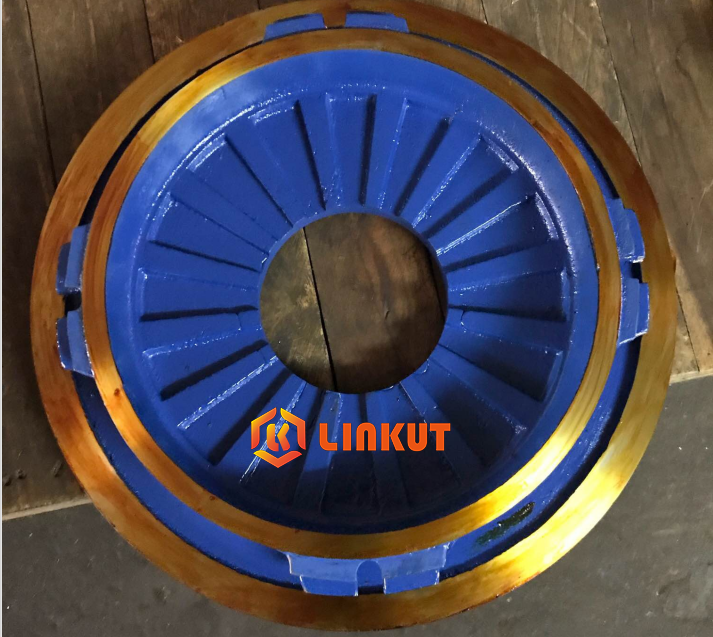

Ni-Hard1 and Ni-Hard4 in nickel hard cast iron have the highest hardness and best wear resistance. Hardness up to HRC61-63.Ni-Hard 4 is widely used in mining machinery,

mineral processing machinery, cement and thermal power equipment, engineering equipment, refractory materials, etc. Ball mill liner, grinding body, centrifugal pump impeller

and outer casing, double-layer rolls, etc. Grinding castings. Due to the large size of these components, the blank machining allowance is large, and the margin is not uniform.

The blanks often have casting defects such as air holes and blisters, and the cutting tools are subject to big impact, which is easy to cause tool damage.

In order to increase productivity, RNGN pcbn inserts are used to machine nickel hard cast iron with a high cutting speed that is 100 times more durable than ceramic tools.

Previous Article:The PCBN Inserts for Processing High Manganese Steel

Next Article: The Characteristics of High Chromium Cast Iron Machining