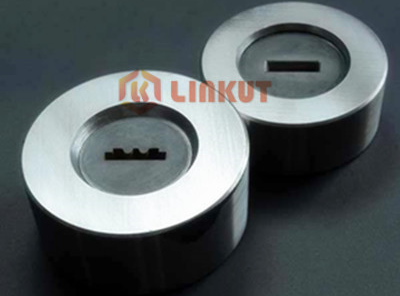

Introduction for Nano-Diamond Composite Coating Drawing Die

The nano-diamond composite coating drawing die is based on cemented carbide (WC-Co) as the substrate, and chemical vapor deposition (CVD) is used to apply

micro-level and nano-level diamond composite coating on the surface of the inner hole of the die. After precision grinding and polishing of the coating, a new mold

is obtained. The micro-nano composite coating on the surface of the inner hole not only has the characteristics of strong adhesion and good wear resistance of the

micron diamond coating, but also has the advantages of high surface finish of the nano diamond coating, small friction coefficient and easy grinding and polishing.

The advantages for the CVD polycrystalline wire drawing die:

1) Drawn aluminum wire is more than 30 times that of cemented carbide die; drawn low carbon steel wire is more than 20 times that of cemented carbide die; drawn

medium carbon steel wire is more than 30 times of cemented carbide die.

2) The aperture change when the mold is scrapped: 0.00 mm, free of mold repair.

3) The working surface has a high finish and remains unchanged.

4) High dimensional accuracy

Previous Article:PCD Cutting Tools for Wood Processing

Next Article: The 2 factors that affect the processing quality of Monocrystal Diamond Chamfering Tools