PCD Cutting Tools for Wood Processing

PCD cutting tool blanks is made of natural or synthetic diamond powder and binder (including cobalt, nickel and other metals) sintered at high temperature (1000 ~ 2000 ℃)

and high pressure (50000 ~ 100000 atmospheres).

PCD woodworking cutter can be divided into PCD saw blade and PCD shaped woodworking milling cutter. The PCD saw blade is formed by welding the PCD cutter blank

on the saw blade substrate and then grinding. Its structure is similar to that of the cemented carbide saw blade. The difference is that the front angle of the PCD saw blade

is smaller than that of the cemented carbide saw blade, which is generally 5 ° to 10 ° and the wedge angle is 65 ° to 75 ° and the blade size is generally 100-450 mm, and

the number of teeth can reach 72 teeth. The main varieties of PCD formed woodworking milling cutter include trimming cutter for processing Al2O3 layer of laminate floor,

PCD groove cutter and PCD furniture forming cutter. The processing method is to copy (or combine) the shape of PCD cutter to the processed wood. The cutting speed of

PCD forming woodworking milling cutter can reach 3000m / min, the cutting speed can reach several meters per minute, and the tool life is dozens or even hundreds times

of that of cemented carbide tools. Because of its high efficiency and high durability, it is especially suitable for mass processing.

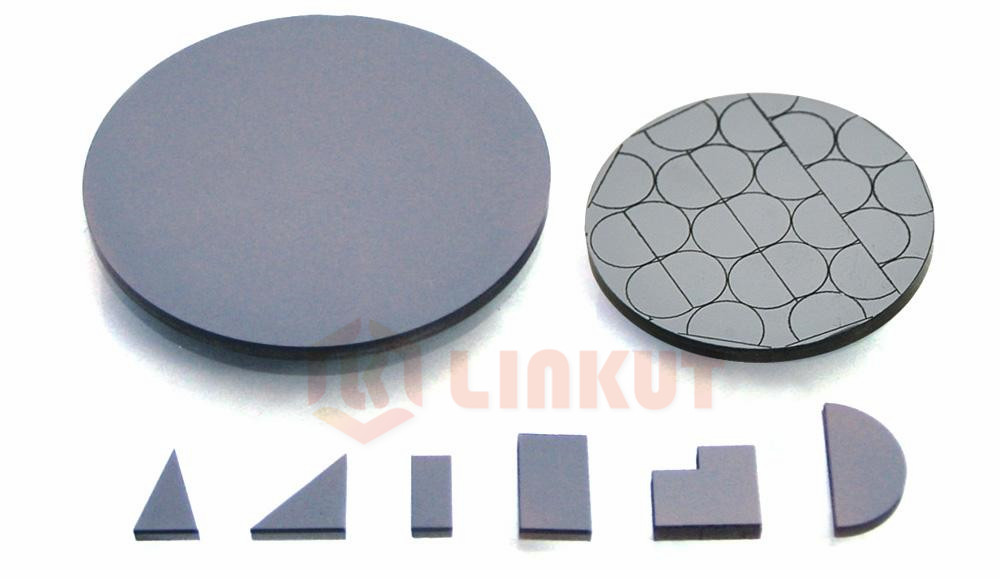

LINKUT PCD blanks diameter is up to 62mm, could be cut into different size to satisfy with your wood machining cutting tools.

Previous Article:The Successful Application of CVD Diamond in Multi Point Dresser

Next Article: Introduction for Nano-Diamond Composite Coating Drawing Die