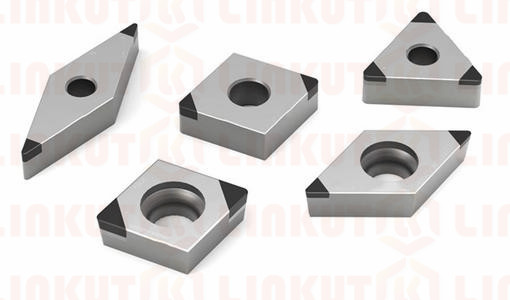

The Failure Modes of Indexable PCD Diamond Tools

Diamond, is the hardest substance in nature. Similar to other indexable pcd diamond tools, the cutting insert will wear out after a long period of use. The main failure

modes are crater wear and built-up edge.

The crescent crater of a diamond insert is common in high-speed machining operations of iron-based or titanium-based alloys. It is attributed to the thermal/chemical

problem of the tool dissolving into the workpiece chip.

Scattered wear and abrasive wear work together to form crescent craters. When machining iron-based and titanium-based alloys, the heat in the workpiece chips will

dissolve and disperse the components of the cemented carbide into the chips, forming "crescent craters" on the top of the tool. The crescent crater will eventually grow

large enough to cause micro-collapsing, deformation and even rapid flank wear.

The built-up edge of the PCD tool is explained as follows by LINKUT technical director:

When the fragments of the workpiece are bonded to the cutting edge by hot pressure welding, built-up edge will occur, which is caused by the presence of chemical

affinity, high pressure and high temperature in the cutting zone. The built-up edge will eventually fall, sometimes along with the blade fragments, and then cause

micro-chips and rapid flank wear.

This failure mechanism is common in viscous materials, low-speed, high-temperature alloys, stainless steel and non-ferrous materials, as well as thread machining and

drilling.

The built-up edge can be identified by abnormal changes in the size or surface roughness of the workpiece and the shiny data on the top of the cutting edge or on the

flank surface.

The built-up edge can be controlled by the following methods: increasing the cutting speed and feed rate, using nitride (TiN) coated inserts, reasonable use of coolant

(such as adding concentration), and selecting geometric shapes or smooth surfaces tools that can reduce the effect.

Previous Article:The Requirements of PCBN Superhard Cutting Tools for Dry Cutting

Next Article: How to Choose the fit Indexable CBN Inserts For Brake Disc Machining?