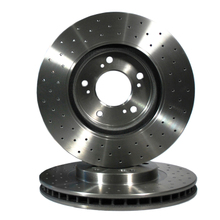

How to Choose the fit Indexable CBN Inserts For Brake Disc Machining?

The material of the brake disc is generally HT250 (grey cast iron), which is one of the important parts in the disc brake device. The indexable cbn insert (PCBN tool) has strong

impact resistance, good wear resistance, high temperature resistance, and can ensure high precision and low roughness. It is an ideal cutting tool for large-scale processing of

gray cast iron workpieces.

1) High hardness, good wear resistance, high temperature resistance

Brake discs are generally HB180-220. Carbide tools are prone to problems such as non-wear resistance and frequent tool changes, which affect production efficiency.

2) High precision and good surface finish

Surface finish and geometric tolerances are the most basic guarantee for the quality of brake discs.

3) Suitable for high-speed cutting

PCBN tool is an ideal tool for mass production of cast iron parts on a fully automatic assembly line. It can withstand high temperature, high speed, and intermittent working

conditions, which can greatly improve processing efficiency.

Such as our solid cbn inserts IBN400 SCGN0904 used for finishing brake disc end face, compared with the famous carbide insert, the tool life improved about 6 times, machining

efficiency improved 2 times.

Previous Article:The Failure Modes of Indexable PCD Diamond Tools

Next Article: The Influence of Drawing Process and Die on Mechanical Properties of Steel Wire