How to improve the service life of PCD Diamond Die Blanks?

The service life of PCD diamond drawing die blanks will not only affect the production cost, but also affect the stability of product quality and production efficiency.

If we want to increase the life of the polycrystalline diamond die, we need to know which factors affect the life of the diamond wire drawing die. LINKUT will give the

most professional mold application solutions.

1) The influence of the production materials on the service life of the drawing die

Die core material is one of the important factors that affect the service life of the mold. The performance of various mold materials in terms of hardness, corrosion

resistance, wear resistance, fracture resistance, plastic deformation resistance, cold and hot fatigue resistance, etc. are very different, so the performance of the mold

material should meet the specific conditions for the use of wire drawing dies. Otherwise, it will inevitably cause the early failure of the mold.

2) The effect of the hole structure on the service life of the drawing die

With the improvement of modern drawing technology, traditional mold design concepts are changing, new concepts have been introduced into modern mold design,

and new "straight" drawing dies are increasingly replacing traditional "arc" drawing dies. After a series of improvements, the service life of the linear drawing die is 3-4

times higher than that of the arc drawing die, and it is especially suitable for high-speed drawing.

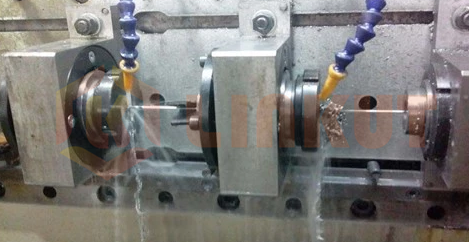

3) The influence of production process on the service life of wire drawing die

The manufacturing process of wire drawing dies requires multiple processes such as forging, machining and heat treatment. If the manufacturing process of any process

is unreasonable, it may be that the performance of the mold steel is reduced, structural defects are formed, and hidden dangers of early mold failure are generated.

4) The influence of working conditions on the service life of wire drawing die

Different thickness and different materials have a great influence on the service life of the wire drawing die. The greater the strength and thickness of the processed material,

the greater the force the mold needs to withstand, and its service life is relatively low. If the processed material and the mold material have a greater affinity, there may be

adhesion and wear with the mold during the molding process, resulting in a reduction in the service life of the mold.

5)The reasonable use and maintenance of the drawing die affects its service life

In the process of using the drawing die, it is reasonably used to maintain the drawing die and improve the repair level of the die. It is an important way to extend the service life

of the die. In addition, good lubrication can effectively reduce friction and friction heat. Thereby reducing mold wear and improving the service life of wire drawing mold.

Previous Article:The Polycrystalline Diamond Tools for Aluminum Alloy Piston Cutting

Next Article: PCBN Indexable Tooling -High-speed High-precision Cutting Hardened Steel