NEWS

What Is PCD and Its Application

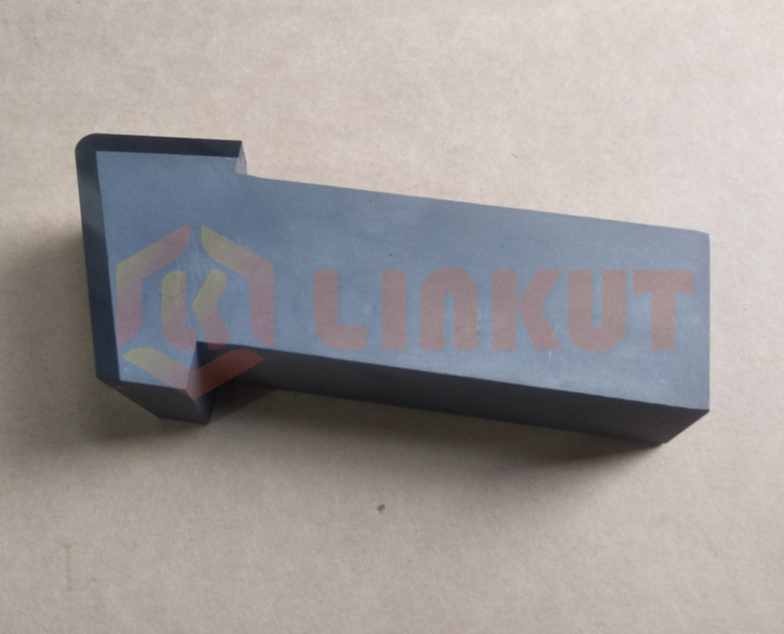

What is PCD

PCD is the abbreviation for Polycrystalline Diamond.

It can be said with certainty that:In the right applications, PCD can significantly reduce your tooling costs as well as your cycle times.

PCD is much harder and more resistant to abrasion the conventional carbide tooling.

It consists of diamond particles (diamond grit) that is sintered with a metallic binder,so one of the hardest and most abrasion resistant tooling materials available.

Like tungsten carbide, PCD is available in multiple quality grades. Better grades include coarser (larger) diamond grain and polished tips that reduce material buildup.

PCD Applications

Materials suited to PCD Tooling include:

Composites, especially abrasive composites like Carbon Fiber.

Carbide alloys and Tungsten

Stone, concrete, asphalt, glass, ceramics, gem stones, and semiconductor materials.

Machining of clean, graded hardwoods.

Non-ferrous metals such as aluminum, copper, and their alloys.

Some soft but tough materials like rubber and resin.

In a word,PCD is a tool material choice ,The actual material removal rates may sometimes be less than conventional tooling, depending on the scenario, but the tool life maybe 10- 50 longer.

Previous Article:Best Choice for Grinding PCD tools With Ceramic Bonded Diamond Grinding Wheels

Next Article: PCD Milling Cutter Is The Optimal Choice for Processing Aluminum Alloy.

More Information Require? Feel free to contact with us!