How to Choose the fit Turning Tools for the Hardened Steel Materials?

The coated alloy inserts, ceramic inserts, cbn turning tools all of them could be used for machining hardened steel materials, which type is the fittest?

Hardened steel refers to a type of steel that has a martensite structure after heat treatment, has a high hardness (greater than HRC50), high strength, and almost no plasticity.

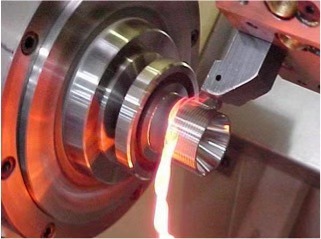

The hardened steel needs the finish machining after heat treatment to ensure the required dimensions and surface roughness of the drawings. However, the hardness of the

hardened steel after heat treatment is difficult to process, and some of the workpieces are interrupted or have high surface precision. Such as gear turning, ball screw machining,

automotive shaft machining.

The choose for the fit turning tools is very important, due to the unique characterisitcs of the hardnened steel. LINKUT could help you find the fittest machining solutions in the shorest

time to meet your machining requirements, no matter for the tipped pcbn inserts or the solid cbn inserts. CNGA1204-2S tipped cbn inserts for turning hardened steel, our BNT4 grade

could help you realize the high speed cutting.

Previous Article:PCD Cutting Tools for the Graphite Machining

Next Article: The Important Role of PDC Cutter Inserts for Drilling