Steel Wire Drawing with Cost Effective PCD Die Blanks

The more the wire drawing die is, the harder the steel wire is. The steel wire undergoes hardening after cold drawing. The tensile strength and hardness of the wire increase with the

increase of the total compression rate. For a steel wire, the wire drawing die becomes more, the total compression rate is bigger and the higher the hardness is.

Phosphate-coated steel wire rope, galvanized steel wire rope, and stainless steel wire rope are all obtained by increasing the compression rate of high-strength steel wire, and then

twisting the wire into a steel wire rope.

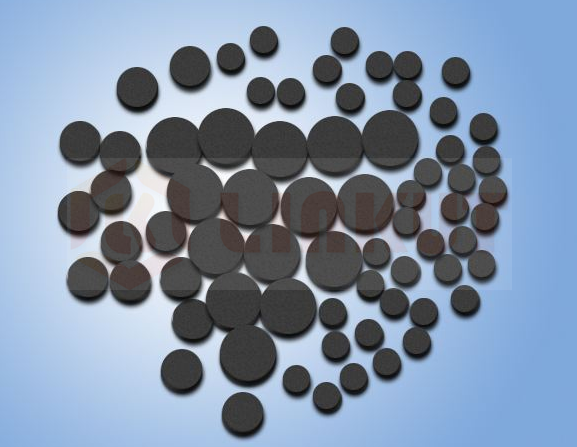

For the steel wire drawing, traditionally, people is using tungsten carbide drawing dies; LINKUT innovative cobalt bond and silicon bond PCD die blanks, with high impact and wear

resistance, could help you realize the high speed steel wire drawing. For stranding and compacting of non-ferrous metals, big size PCD wire drawing die blanks could be supplied too.

Previous Article:Why CBN Cutting Tools are currently the best choice for machining Large Casting Roll?

Next Article: Why choose the superhard turning tools pcd inserts for the ferrous metal Machining?