The Failure Mode of Polycrystalline Diamond Compact Cutters-Smooth Wear

The micro chip breaking, macro cracking and peeling failure of polycrystalline diamond compact (PDC) bit cutters cutting teeth are the main forms and causes of early failure of PDC bit.

To prevent early failure of PDC bit, improvement measures should be taken from design, material manufacturing and use.

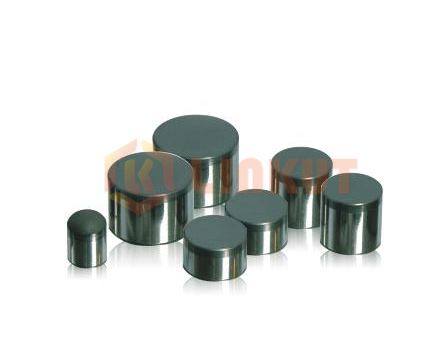

Polycrystalline diamond composite drills use PDC made of artificial polycrystalline diamond as cutting teeth. Diamond composite (PDC) cutting bit require both high strength, hardness,

and certain corrosion resistance.

The smooth wear feature of PDC cutting teeth is that the wear surface is relatively smooth on the macro level. Both the diamond layer and the WC base are worn during the cutting

process to form a wear plane. During the cutting process, because the WC hardness is lower than the diamond, the first wear is the WC base, so the diamond near the WC base loses

the effective support of the WC, forming the diamond "lip" edge, under the action of cutting force, the lip is subjected to tensile stress, which leads to the initiation and expansion of

tensile stress cracks. Eventually, the lip breaks, resulting in a reduction in the contact area between the unbroken diamond layer and the rock. The greater the stress, the faster the

rupture of the diamond cutters. Once the entire contact surface of diamond cutter is damaged, the WC base will again effectively contact the rock, and then the WC base will be

preferentially worn away, forming a cycle of smooth wear process, but compared with other failure modes, the smooth wear process is slow. It is a normal form of failure. Formally due

to the formation of the "lip" zone, the contact area of the remaining diamond and rock is reduced, the cutting force per unit area is increased, and a self-sharpening effect is formed.

"Self-sharpening"effect helps to maintain the effective cutting force of the drill bit.

No matter for the 1013, 1304, 1308, nor for the 1616, 1916, etc high end PDC could be supplied by LINKUT.

Previous Article:CBN PCD Tools for Cutting Cemented Carbide Precision Parts

Next Article: Turning and Milling of Universal Joints of Automobile