Turning and Milling of Universal Joints of Automobile

The professional turning and milling solutions could be provided for your universal joints machining of the Automobile.

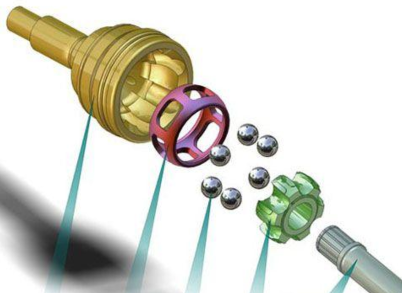

The universal joint is one of the key parts of modern automobile. Its function is to transfer the power of engine from gearbox to two front wheels and drive the car at high speed. The universal joint is mainly composed of steel ball, star sleeve, spherical shell and other parts. The appearance of this universal joint promotes the progress and development of front wheel and four-wheel drive vehicles.

The machining difficulties of the universal joints are as follows:

1) The hardness of spherical shell, star sleeve etc is high after overheated treatment, some of them belong to interrupted cutting condition;

2) The parts tolerance are strictly required, which is difficult to be guaranteed by ordinary machine tools;

3) There are too many steel balls, the structure of the universal joints parts is complex and difficult to process.

Why Choose CBN inserts for turning and milling Universal Joints Parts?

At present, the univeral joints parts are mainly produced in batches. In the process of machining with carbide and ceramic tools, due to the high hardness of the parts and the interrupted cutting in some parts, the cutting edge of the tools will wear or collapse quickly, resulting in the parts tolerance not being guaranteed. Therefore, LINKUT CBN tools are the fittest products for turning and milling the universal joints parts, so as to prolong the tool life and improve the productivity and product quality.

At the same time, LINKUT can also provide the wiper cbn turning inserts and coated pcbn inserts for your application, help you improve the machining efficiency, precision and tool life.

Previous Article:The Failure Mode of Polycrystalline Diamond Compact Cutters-Smooth Wear

Next Article: Performance Test Method of PDC and Diamond Cutters