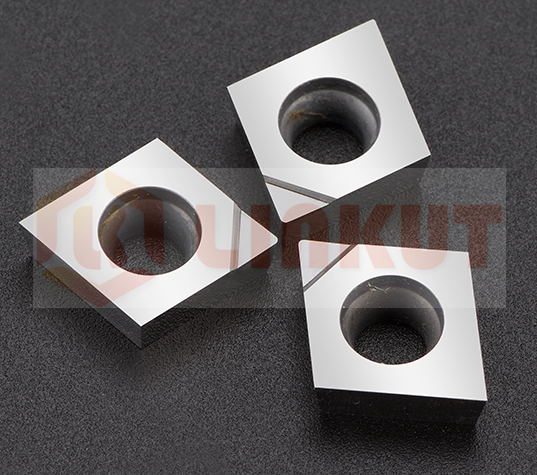

PCD Tools for efficient Turning of Ceramic Materials

Ceramic materials have high hardness, high brittleness, and low thermal conductivity, making them a difficult to process material. LINKUT PCD tools can meet your machining

requirements for high precision, high surface quality, high efficiency and low cost of ceramic parts, such as our CCGW, VCGW PCD Inserts.

For rough machining of ceramic parts, polycrystalline diamond (PCD) tools are generally selected. Polycrystalline diamond (PCD) tools are made of artificial diamond particles

sintered at high temperature and pressure. Rough machining.

For the finishing of ceramic parts, micro-cutting is performed using natural single crystal diamond tools (with small cutting depths and feeds). Natural single crystal diamond

cutting tools have sharp cutting edges, high hardness, abrasion resistance 10 times that of alumina ceramics, and small thermal wear during cutting, which can ensure high

dimensional accuracy and surface finish of ceramic materials. At the same time, it is also used for other parts that are difficult to machine such as grooving and contouring.

Previous Article:CBN Insert Interrupted Turning Hardened Steel

Next Article: The Coating Introduction for the CBN PCD Cutting Tools