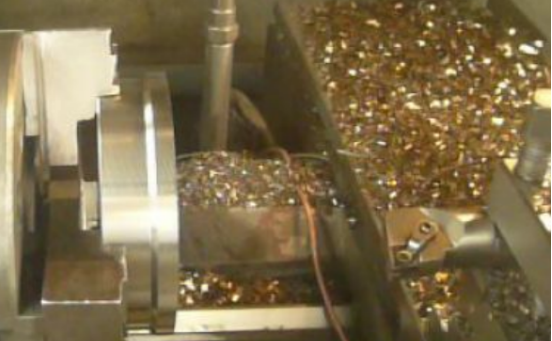

Metal softening effect of dry cutting of PCBN Inserts

Due to the high temperature hardness and thermal stability of the PCBN inserts, the cutting speed can be cut at a higher cutting speed. Under the action of higher cutting heat, the metal

of the cut layer is softened and the hardness is lowered, which makes the cutting process easier. And the cutting tool also guarantees a high life, this effect is called the metal softening effect.

The determinant of the metal softening effect is the cutting temperature. The test shows that the cutting speed has a greater influence on the cutting temperature than the feed rate, and the

effect increases with the increase of the feed rate; the influence of the back cutting depth on the cutting temperature is also Larger, and the degree of influence increases as the hardness of

the workpiece material increases.

Previous Article:Surface Quality of Dry Cutting of PCBN Tools

Next Article: Comparison of Cutting Performance and Failure Mechanism of PCD and CVD Diamond Tools