What are the characteristics of the wire drawing process?

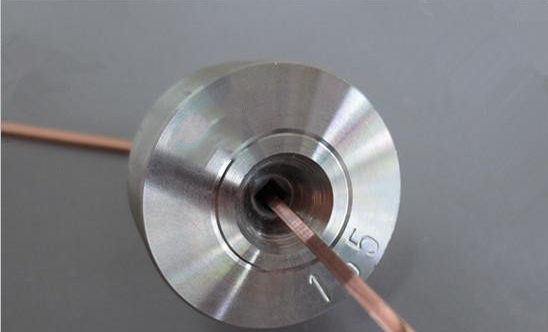

Drawing is a plastic working method in which an external force acts on the front end of the drawn metal to pull the metal blank from the die hole smaller than the cross section

of the blank to obtain a product of a corresponding shape and size. In metal drawing or drawing, the metal sheet or blank is drawn by drawing a punch. The punch enters the

die to shape the sheet.

The application range of metal drawing production:

Wires, thin pipes, including some profiles can be produced by drawing.

Drawn products include wire and thin tubing that are wound into a roll; and straight products such as round, hexagonal, square profiles, profiles, and slightly thicker pipes of

various cross-sectional dimensions.

The metal drawing processing method has the following characteristics:

1) The drawing method can produce a product with a very large length and a very small diameter, and can ensure that the cross section is completely uniform along the entire length;

2) The shape and size of the drawn product are accurate and the surface quality is good. The dimensional accuracy is plus or minus a few hundredths of a millimeter, and the surface

characteristics of the surface roughness reach the mirror surface of the auroral surface.

3) The mechanical strength of the drawn product is high;

4) The disadvantage of the drawing method is that each processing rate is small, the number of pulling passes is large, and the energy consumption is large.

Previous Article:Thermal Wear and Decobalting of PDC Cutter Inserts

Next Article: Machining Characteristics of Wear-resistant Low-alloy Cast Iron Parts and Chilled Iron Parts