Machining Characteristics of Wear-resistant Low-alloy Cast Iron Parts and Chilled Iron Parts

LINKUT solid cbn inserts have very successful application for the wear resistant cast iron and chilled iron parts machining.

1) Wear-resistant low-alloy cast iron and chilled cast iron are hard and brittle materials with high hardness and high thermal strength. When roughing, the unit cutting

force is large, up to 3000MPa, which has a strong impact on the tool and easily causes cutting vibration. Increases tool wear.

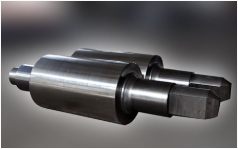

2) Wear-resistant low-alloy cast iron and chilled cast iron are commonly used to make various rolls and other castings. The casting has a large structural size and a large

machining allowance. Large cutting depths and feeds are often used for cutting. Produces large cutting forces and requires high tool strength and process system stiffness.

3) Wear-resistant low-alloy cast iron and chilled cast iron have high strength and high heat strength, especially for processing large castings. The cutting tool has a long working

time and increases the cutting temperature, so that the strength of the tool material is lowered, and the deformation of the tool body or the welding of the welding tool may occur,

resulting in damage to the tool.

4) The structure of wear-resistant low-alloy cast iron and chilled cast iron is white mouth, its nature is hard and brittle. When cutting and cutting the goods during cutting, the

workpiece is prone to chipping, causing the workpiece to become waste or damage the tool.

5) The surface of the wear-resistant casting blank has uneven machining allowance, and it is prone to casting defects such as air holes and blisters. The tool is subjected to large

impact during cutting, which causes tool damage and reduces machining accuracy and surface quality.

6) When cutting wear-resistant low-alloy cast iron and chilled cast iron, the chips are broken. The cutting instantaneous temperature is higher, the processing stability is lowered,

and the surface roughness value of the workpiece is increased. It should also prevent damage to the operator from the chips.

Previous Article:What are the characteristics of the wire drawing process?

Next Article: PCD Cutting Tools for the Graphite Machining