What We Know for MCD and CVD Diamond Tools?

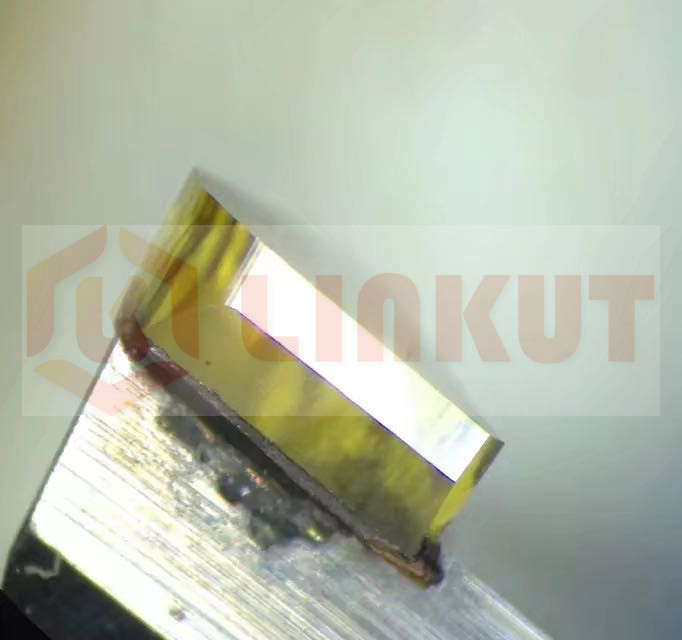

The monocrystal diamond tool is currently the main cutting tool in the field of ultra-precision machining. The cutting tool generally has a mass greater than 0.1g and a minimum

diameter length of not less than 2mm. It can achieve mirror processing, and can produce extremely high workpiece accuracy and extremely low surface roughness value, the effect

of cutting is very bright, is a recognized and ideal ultra-precision machining tool.

1) Synthetic (high temperature and high pressure synthesis) mono crystal diamond (MCD tool):

It is one of the Ib type mono crystal synthetic diamonds. Nitrogen [N] is mostly dispersed or solid dissolved in the crystal. The synthetic mono crystal diamond is artificially synthesized

as the name implies. It is oxygen-free and high temperature (above 1000 ° C) high pressure Synthesized in the environment, because it has the same high hardness, high wear resistance

and high thermal conductivity as diamond.

Because it is a mono crystal with diamond, the nature of no crystal boundaries can produce a very sharp edge quality, which is a level that other materials cannot reach. It has long been

used in the production of ultra-precision diamond tools, polishing tools and wear-resistant components. The current maximum size of synthetic mono crystal diamond can reach 8mm.

2)) Man-made (CVD synthetic) mono crystal diamond:

Belongs to IIa type diamond type mono crystal synthetic diamond, nitrogen [N] <1 ppm, [B] <0.05 ppm, CVD synthesis mono crystal diamond process environment is in the chamber of

the mixture of hydrogen and carbon, using chemical vapor It is synthesized by deposition method (CVD).

This is a high-quality mono crystal diamond synthesized by ultra-high technology, which can be completely colorless and transparent, with almost no impurities, has higher wear resistance

and better thermal conductivity coefficient, and can make the processed object have more A higher quality processed surface, and if the doping gas is selectively introduced during the

growth process, a variety of colored diamonds can be prepared.

LINKUT always supply the high quality MCD and CVD insert tools for your high accuracy machining.

Previous Article:The Knowledge for Oxidized surface repair of Wire Drawing Die Tools

Next Article: How to Choose the optimal cutting paramters of PCBN inserts for turning Brake Disc?