Why LINKUT CBN Inserts could be used for turning the workpiece above HRC60?

Why LINKUT CBN inserts could be turning the workpiece>HRC60?

1) LINKUT CBN tool has high hardness and wear resistance. The hardness of its tool body is between HRC95-100, so it has good wear resistance. It can easily

turn workpieces above HRC60.

2) CBN tool has high thermal stability and high temperature red hardness, and can withstand high temperature of 1400-1500 ℃. Therefore, the temperature

generated when machining workpieces above HRC60 will not lead to rapid wear or edge chipping.

3) CBN cutting tools has low friction coefficient and excellent anti bonding ability, so it is not easy to form retention layer or chip buildup when machining workpieces

above HRC60, thus obtaining high surface quality.

4) In high-speed machining, PCBN insert are not easy to react with ferrous materials at 1200 ℃, so dry cutting is often used in machining with CBN cutting insert. In

green machining of black metal materials, it has become an increasing trend to select PCBN turning insert.

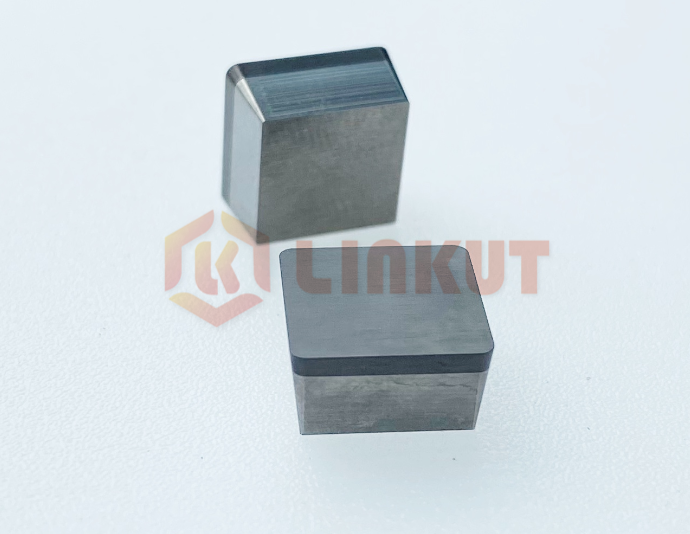

Full face cbn insert, solid cbn insert, cbn insert with dimple, cbn insert with hole, tipped pcbn insert, brazed cbn inserts all of them could be provided based on customers'

detail requirements.

Previous Article:Advantages of LINKUT PCBN Cutting Tools Turning Clutch Compressing Disc

Next Article: The Wide Application of Diamond Cutting Tools