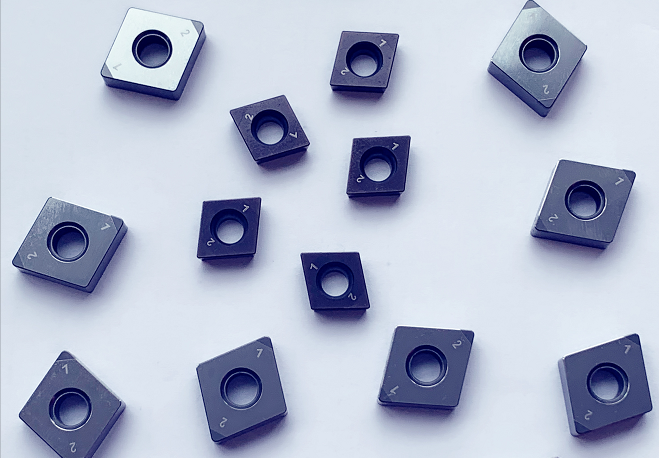

Characteristics of Synthetic Polycrystalline Diamond Tools

Polycrystalline Diamond Tools with extremely high hardness and unique machine performance is sintered by high temperature and high pressure of diamond particles and catalyst

turbidity.

1) High strength and toughness

2) Uniform hardness and no directionality

3) Diamond polycrystalline has stable cutting performance

Large grain diamond single crystals can be sharpened after grinding, but they are blunt after a certain period of time, so the cutting force increases, the roughness of the working

surface becomes worse, and the tool must be reground. In contrast to diamond polycrystals, the cutting edge can continue to work with less cutting force after being blunt and rounded,

and the surface roughness of the workpiece being processed is still good, obviously because each particle is used as a cutting point is separately at work.

4) It is not easy to produce built-up edge.

5) Tools can be designed.

Previous Article:What we know for LINKUT PCD/PDC Cutter Inserts?

Next Article: The General Information for PCD Inserts Grades