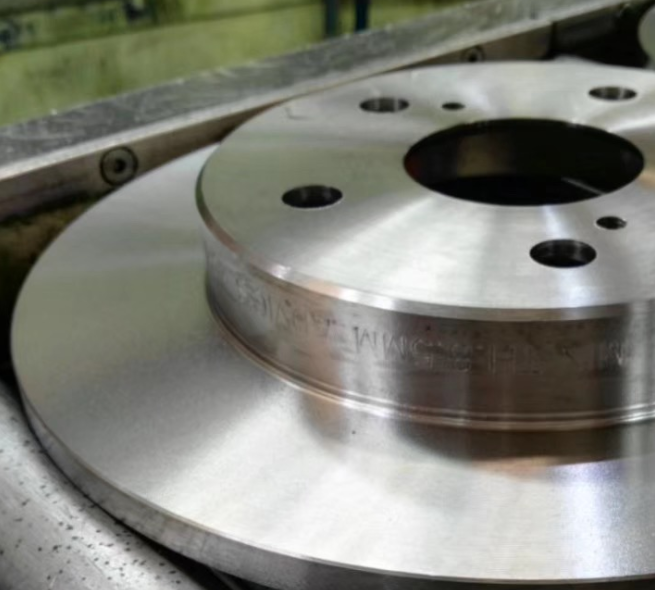

SNGN CBN Inserts for Brake Disc Machining

The brake disc machining can be used coated cemented carbide inserts, pcbn inserts, ceramic inserts, etc. These three inserts have their own processing range and conditions,

but in terms of processing efficiency and investment cost, the CBN inserts is the most cost-effective.

Such as LINKUT SNGN series SNGN0903, SNGN1204 CBN turning inserts are widely used in brake discs because they can achieve high-speed cutting and meet the requirements

of automated CNC machining, which can improve the processing efficiency of brake discs by 10 times for rough and finishing operations. On the other hand, CBN inserts have multiple

cutting edges and high indexing accuracy, making them more suitable for vertical and horizontal CNC machine tools for machining hardened steel parts such as auto parts, bearings and

rolls. Due to the high rigidity of the CNC lathe, the high precision of manufacturing and tool setting, and the manual and accurate manual compensation or even automatic compensation,

the CBN insert can be used with CNC machine tools to process parts with high dimensional accuracy and achieve grinding. .

The cubic boron nitride tool is suitable for the automotive industry to process the inner, outer, end and chamfering of various brake drums, brake discs and hubs. It can also process various

types of discs, shafts, bores and other components.

Previous Article:Effect of Drawing Conditions on the Service Life of Wire Drawing Die Tools

Next Article: Diamond Wire Drawing Die for Drawing Copper Plating Wire