PCD Tool Excellence in Graphite Product Machining - A Success Story from LINKUT Company

With the rapid development of technology, graphite, as a high-performance material, has demonstrated its unique advantages in multiple fields. However, the hardness and brittleness of graphite also pose challenges in the machining process. In this context, LINKUT Company, with its advanced PCD (Polycrystalline Diamond) tool technology, has successfully addressed the difficulties in graphite product machining, setting a new benchmark for the industry.

Case Background

A renowned new energy vehicle manufacturer encountered issues such as low machining efficiency and severe tool wear when manufacturing fuel cell bipolar plates from graphite. Graphite bipolar plates, as critical components of fuel cells, directly impact the performance and production costs of the entire fuel cell stack. Therefore, the manufacturer urgently needed a tool solution capable of efficiently and stably machining graphite materials.

Solution

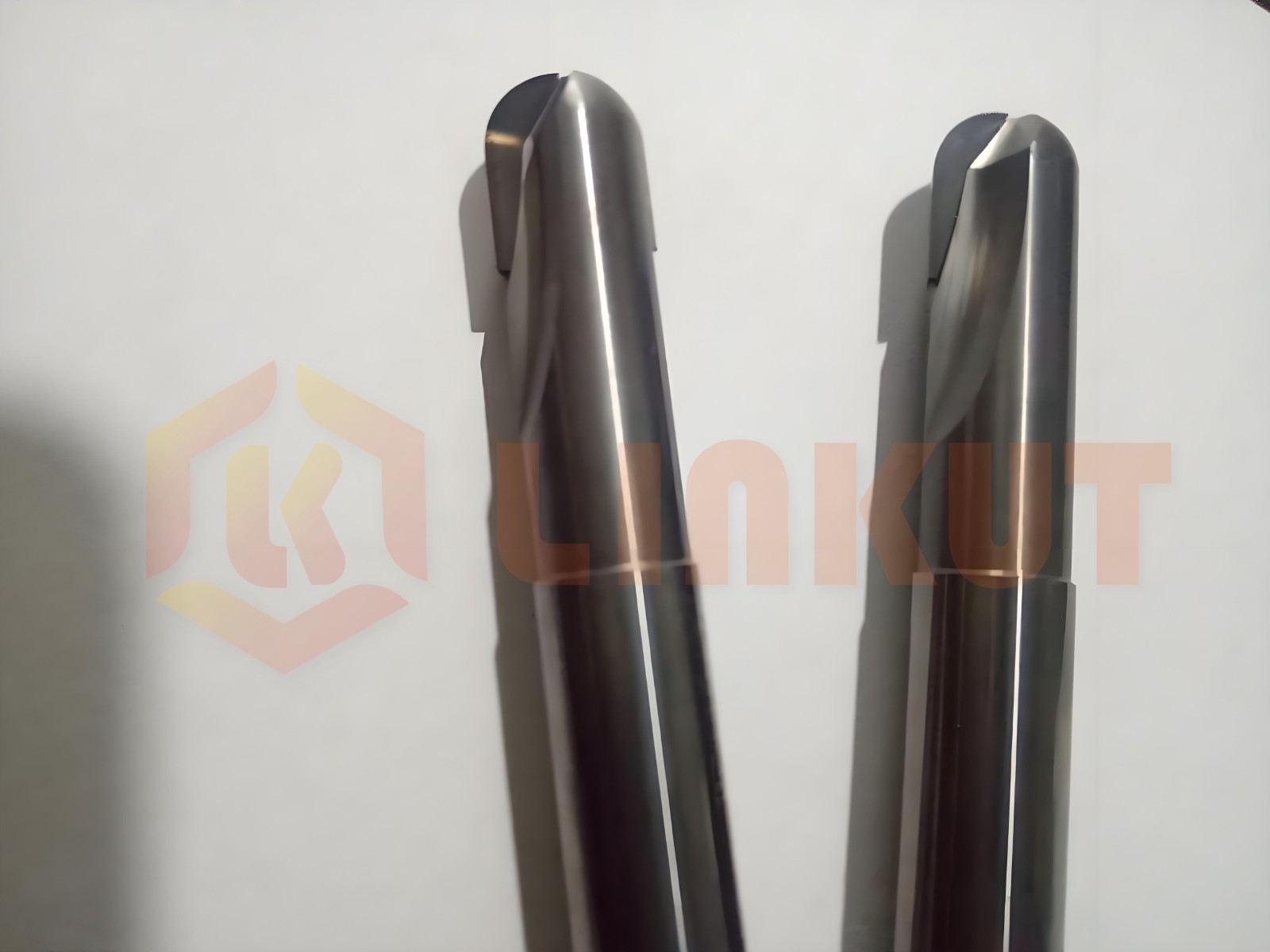

In response to the specific needs of the customer, LINKUT Company recommended its self-developed PCD milling cutter. This tool, made of high-quality PCD material, exhibits extreme hardness and wear resistance, effortlessly tackling the machining challenges of graphite materials. Additionally, LINKUT Company optimized the geometric angles of the tool based on the machining characteristics of graphite materials, further enhancing cutting efficiency and tool durability.

Implementation Results

After introducing LINKUT's PCD milling cutter, the new energy vehicle manufacturer witnessed a significant improvement in the machining efficiency of graphite bipolar plates. Compared to previously used tools, the PCD milling cutter offered faster cutting speeds and less wear, effectively reducing production costs and machining time. Moreover, the exceptional performance of the PCD tool ensured the machining accuracy and surface quality of graphite bipolar plates, providing more reliable support for the fuel cell systems of new energy vehicles.

Technical Highlights

High Hardness and Wear Resistance: LINKUT's PCD tools are made of high-quality PCD material, exhibiting extreme hardness and good wear resistance, capable of easily handling the machining challenges of hard materials like graphite.

Optimized Geometric Angles: Based on the machining characteristics of graphite materials, LINKUT optimized the geometric angles of the tools, effectively improving cutting efficiency and tool durability.

Efficient Machining: PCD tools offer faster cutting speeds and less wear, significantly enhancing the machining efficiency of graphite products and reducing production costs.

High Precision and Quality: The exceptional performance of PCD tools ensures the machining precision and surface quality of graphite products, meeting customers' demands for high-quality products.

Conclusion

LINKUT's PCD tools have demonstrated outstanding performance and stability in graphite product machining, not only improving machining efficiency and product quality but also reducing production costs. This success story fully showcases LINKUT's leading position and technical expertise in the field of PCD tools. In the future, LINKUT will continue to focus on the research and development of PCD tools, providing more customers with efficient and reliable tool solutions.

Previous Article:High - Efficiency Precision Turning - LINKUT PCD Motor V - Block

Next Article: Application of LINKUT PCD Tools in Engine Machining