Brazed PCBN Inserts for Cutting Brake Drums

As one of the main consumables of automotive parts, brake drums have been in high demand and production capacity with the rapid development of the automotive industry.

However, the precision requirements for brake drums are high, which places higher demands on cutting tools. The brake drum is generally made of HT250 material and has a hardness of HB210-230.

PCBN has a very high hardness, second only to diamond, and is very suitable for processing superhard materials, making it one of the preferred choices for processing cast iron materials.

LINKUIT is a pioneer of CBN tools for processing hard materials. Faced with the quality and efficiency requirements of brake drums, we recommend IB400 tool materials to assist CNC machine tools in efficiently cutting brake drums.

IBN400 is a generation of CBN material developed by LINKUT for cast iron processing. It mainly uses embedded CBN tools, and can also customize overall polycrystalline CBN tools according to user requirements.

Spare Parts: Brake Drum

Material: HT250 HB210-23

Application: Finishing

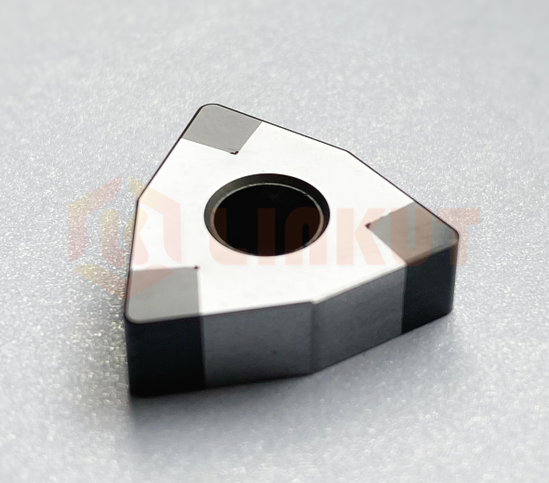

Inserts: WNGA080412-6S Grade: IB400

Cutting parameters: Vc=600m/min f=0.2mm/r ap=0.5mm

Compared with Coated Alloy Inserts:

The efficiency increased about 100%; The tool life increase 3.5 times.

Brazed PCBN Inserts: More flexible clamping methods; More cutting edges.

Previous Article:A Excellent Tool for Precision Manufacturing - PCD Micro Drill

Next Article: Polishing Edge PCD Tools Improving Surface Roughness of Nonferrous Metal