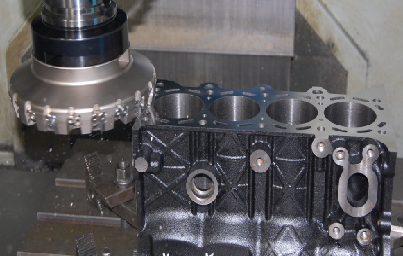

CBN Inserts for Milling Application in Auto Parts Processing

CBN inserts is not suitable for using cutting fluid in milling application, because the milling process is already the interrupted cutting. If the cooling effect of cutting

fluid is added, the temperature difference between the CBN tools and the temperature difference is extremely large, it is easy to crack, and the tool life will be

dramatically shorten.

CBN tools have been adapted to the needs of high-speed machining in the automotive industry and have been widely used in rough machining, semi-finishing, and

crankshaft oil cover for the top and bottom of cylinders in the machining of cast iron cylinders for automotive engines. The cutting speed of the crankshaft hole opening

surface can reach 800-1000m/min or more. At such a high cutting speed, the tool life can still reach hundreds of workpieces. Our IBN300 pcbn insert is designed for

milling that improve processing efficiency while maintaining the surface finish of the parts in terms of milling grey cast iron and hardened steel.

Previous Article:The Characteristics of the Hardened Steel

Next Article: Small Knowledge for PCD Tools