-

2020/03/02

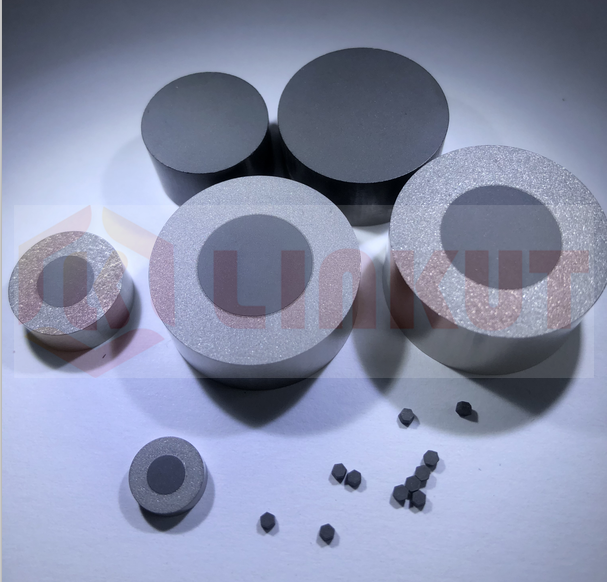

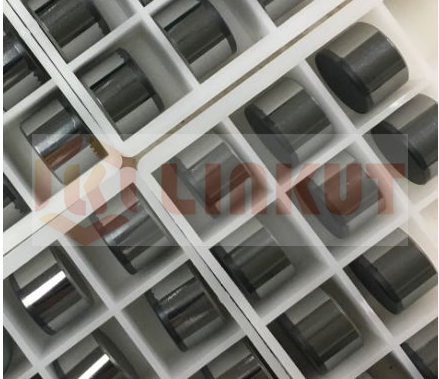

The Production Assembly of PDC Cutting Inserts

Diamond composite cutting insert (PDC) are widely used in oil, geology, coal field mining and drilling, and multiple fields. How to keep the performance of PDC tools stable and continuous improvement is not only direc...

-

2020/02/27

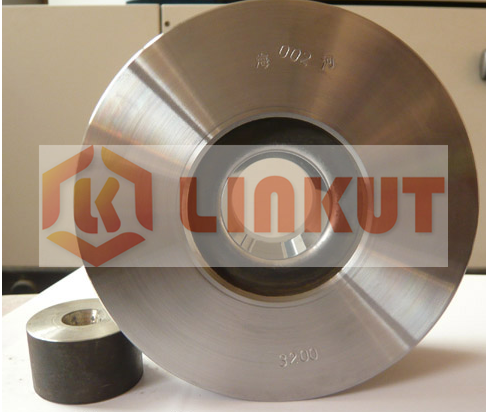

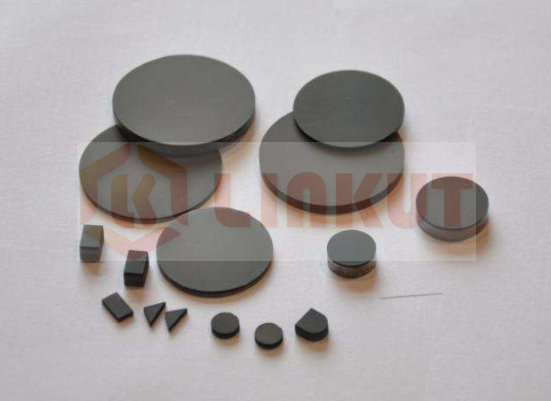

LINKUT Available Polycrystalline Diamond Wire Drawing Die Blanks

Wire drawing die core is the core component of diamond wire drawing die. LINKUT could supply the fittest type based on your drawing application.

-

2020/02/20

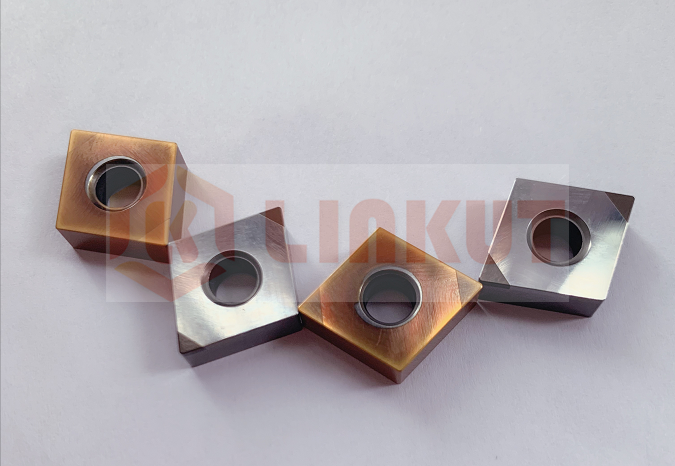

Hardened Steel Finish Turning with PCBN Inserts

For finish turning hardened steel, the CBN content of the pcbn inserts is relatively low. Fine grained CBN is generally used for finishing.

-

2020/02/17

Wire Drawing Die Insert Blank-The core component of PCD Drawing Die

The wire drawing die insert blank is the core component of the diamond wire drawing die. PCD Core has been widely used in the wire drawing industry.

-

2020/02/10

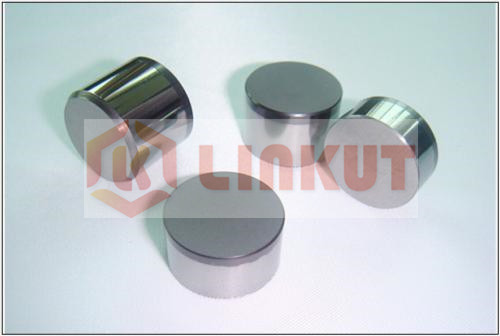

LINKUT High Wear Resistance PDC Cutter

Polycrystalline diamond composite have been widely used in geological exploration, coal field mining, and oil drilling. The main technical indicators for measuring the quality of PDC are heat resistance, wear resistan...

-

2020/01/24

Basic maintenance of PDC Cutter Drilling Tool

PDC cutter drilling tools is suitable for coal mine, geology, engineering.Diamond composite drill bit is regarded as one of the relatively expensive wearing parts in underground engineering. Therefore, we should be ca...

-

2020/01/21

Factors Affecting the Life of Diamond Wire Drawing Die-Lubricant

The production of stainless steel wire and cable industry is inseparable from the diamond wire drawing die, especially in the field of fine wires and micro wires. In the process of drawing, the quality and supply of s...

-

2020/01/18

High Wear-resistant and Impact-resistant PDC Cutter Blank

PDC Cutter Blank is a composite material composed of diamond and cemented carbide matrix. It has the characteristics of high hardness and good wear resistance. It is widely used in oil drilling, geological exploration...

-

2020/01/15

Hardened Steel Turning Coated PCBN Inserts vs Uncoated CBN Inserts

What are the benefits of LINKUT Coating cbn inserts? Improved heat resistance Increased wear resistance Enhanced bonding strength Better toughness

-

2020/01/10

What are the factors that affect the PDC Cutter Bit footage?

The PDC cutter bit performance is directly related to drilling efficiency, quality, cost and even safety. T

-

2019/12/30

The Characteristics of LINKUT CBN Inserts for Brake Drum Machining

The main features of LINKUT innovative CBN inserts which are with excellent wear resistance, toughness and impact resistance and can adapt to both dry and wet cutting.

-

2019/12/25

How to use PCBN Inserts Reasonably?

Due to the excellent cutting performance of PCBN inserts materials, it is particularly suitable for processing hardened steels with hardness>HRC45, wear-resistant cast iron, heat-resistant alloys>HRC35, and pearlite g...

More Information Require? Feel free to contact with us!