Types and Applications of Diamond Cutting Tools

Diamond cutting tools are widely used in precision machining, mainly including three types, and their applications are also different.

1. Single crystal diamond cutting tools

Single crystal diamond cutting tools are currently the main cutting tools for ultra precision machining of non-ferrous metals, which can achieve mirror finish machining and produce extremely high workpiece accuracy and extremely low surface roughness. The cutting effect is very bright, which is recognized as an ideal and irreplaceable ultra precision machining tool.

Characteristics of single crystal diamond cutting tools:

1) High hardness and good wear resistance

2) The service life is 100 times or even hundreds of times longer than that of hard alloy cutting tools

3) Low friction coefficient: The friction coefficient between diamond cutting tools and non-ferrous metals is lower than that of other cutting tools. The friction coefficient is low, and the deformation during processing is small, which can reduce cutting force.

4) The cutting edge is very sharp: The cutting edge of diamond cutting tools can be ground very sharply, enabling ultra-thin cutting and ultra precision machining.

Application of single crystal diamond cutting tools:

Diamond cutting tools are officially used for fine cutting of non-ferrous metals (such as gold, silver, platinum) and non-metallic materials at high speeds, as well as for processing parts such as laser reflectors, astronomical telescopes, and optical instruments.

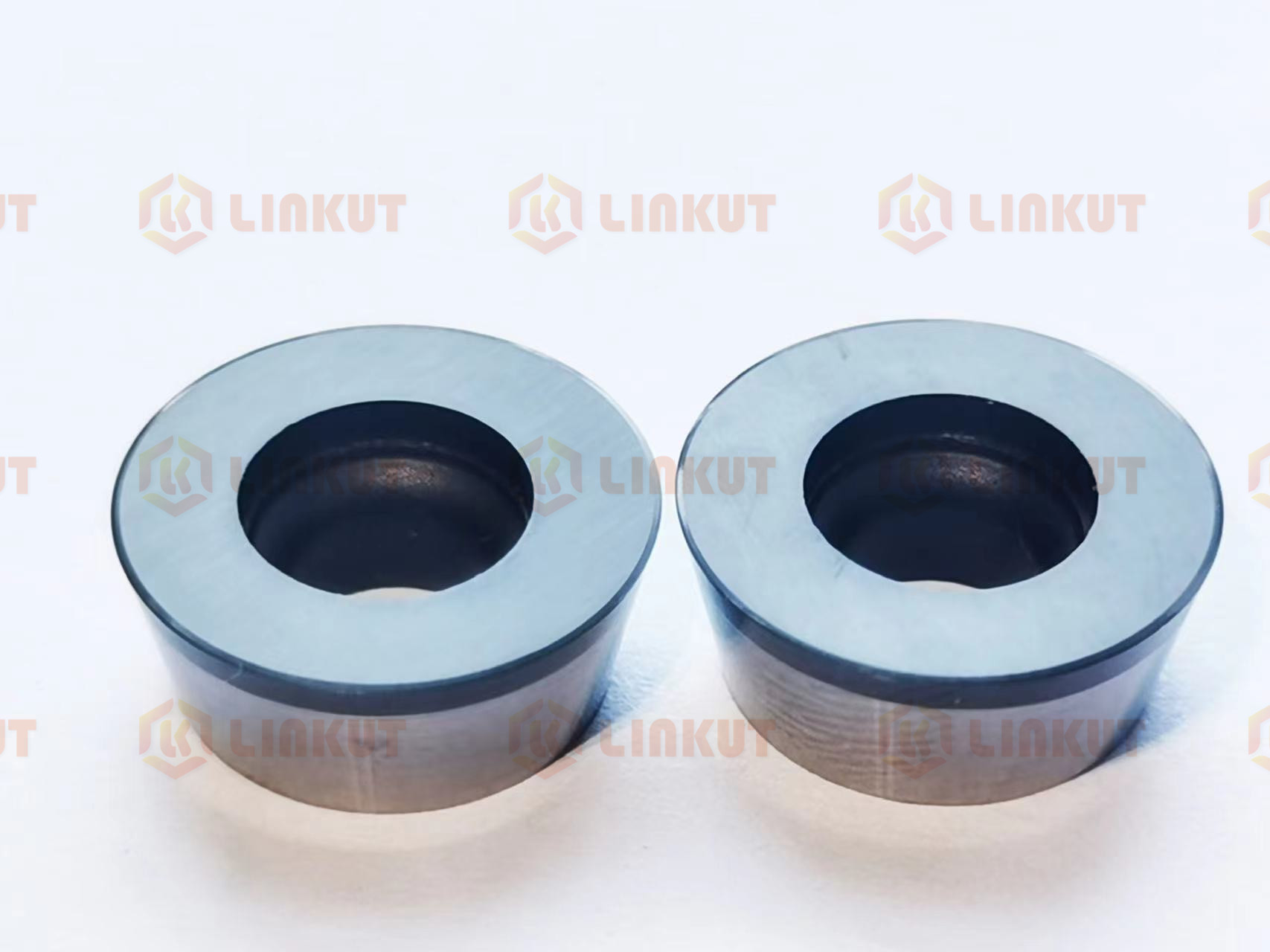

2. Polycrystalline Diamond (PCD)

PCD cutting tools are tools made of superhard material PCD (polycrystalline diamond) and tool substrate through special processes. Mainly used for processing wear-resistant non-ferrous metals, their alloys, and non-metallic materials.

Characteristics of PCD cutting tools:

1) High hardness, high compressive strength, and good wear resistance!

2) Compared with hard alloy cutting tools, it can maintain sharpness and cutting efficiency over a long cutting process, and its service life is much longer than that of hard alloy cutting tools!

Application of PCD cutting tools:

PCD milling cutters, boring cutters, and other CNC cutting tools are widely used in the automatic production lines of high-strength and high hardness silicon aluminum alloy parts, such as skirts, cylinder blocks, transformers, etc. for aluminum alloy pistons in automobile and motorcycle engines.

Due to the high silicon content of these parts, hard alloy cutting tools are difficult to handle. However, the service life of PCD cutting tools is much higher than that of hard alloy cutting tools, dozens or even hundreds of times longer, and can greatly improve cutting speed, processing efficiency, and workpiece processing quality.

At present, polycrystalline diamond (PCD) cutting tools have been widely used in the processing of non-ferrous metals, automobiles, motorcycles, aerospace, wood, carbon fiber, and alloy components.

3. CVD diamond cutting tools

CVD diamond refers to the synthesis of diamond films on heterogeneous substrates (such as hard alloys, ceramics, etc.) using chemical vapor deposition (CVD). CVD diamond knives have the same structure and characteristics as natural diamond.

Characteristics of CVD diamond cutting tools:

The performance of CVD diamond is very close to that of natural diamond, combining the advantages of natural single crystal diamond and polycrystalline diamond (PCD), while also overcoming their shortcomings to a certain extent.

Application of CVD diamond cutting tools:

CVD diamond cutting tools can cut non-ferrous metals, silicon aluminum alloys, hard aluminum alloys, composite materials, etc., achieving ultra precision machining. CVD diamond cutting tools are considered ideal tools for processing non-ferrous materials!

Previous Article:The Difference Between PCD and CBN Cutting Tools

Next Article: Hard Alloy Cutting Solutions - PCD Tools