Application of PCD Inserts Tooling in Machining 5C Parts of Automobile Engine

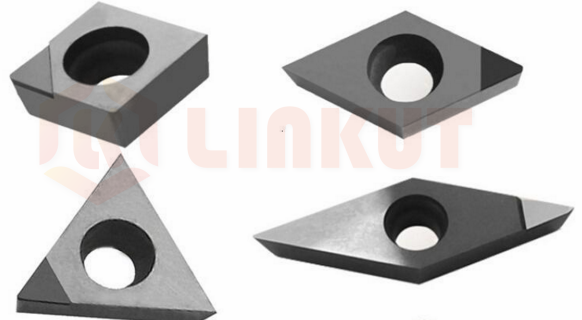

PCD and CBN inserts tooling are widely used in the automotive industry engine with their stable turning/milling performance and service life.

With the continuous development of automobile manufacturing industry and the continuous updating of manufacturing technology, the requirements of high precision,

high efficiency and long life are put forward for the cutting tools for machining 5C parts of automobile engine (cylinder block, cylinder head, crankshaft, camshaft and

connecting rod).

The requirements of cutting technology for machine tool performance and stability are higher and higher. Conventional cemented carbide tools can not meet the needs

of processing technology. In automobile engine processing, high precision, high efficiency and cost reduction are very important and key for engine manufacturers. At

the same time, improving engine performance and reducing fuel consumption are also urgent needs of manufacturers.

PCD tool has a significant advantage in automotive engine processing. Because of the low hardness and high toughness of aluminum alloy, it is difficult to cut. In the process

of machining, aluminum alloy is easy to bond with the tool material and appear cold work hardening phenomenon. In the low speed cutting, chip buildup is easy to occur on the

rake face of the cutting tool. Therefore, the stable material properties and processing performance of PCD insert are excellent in the processing of aluminum alloy and other

materials. When milling aluminum alloy cylinder head, LINKUT indexable pcd insert can feed 3mm / R, with higher efficiency and longer tool life.

Previous Article:Application of PCBN Cutting Tools in Rail Transport

Next Article: PCD Milling Tool-The Great Choice for Processing Carbon Fiber Composite