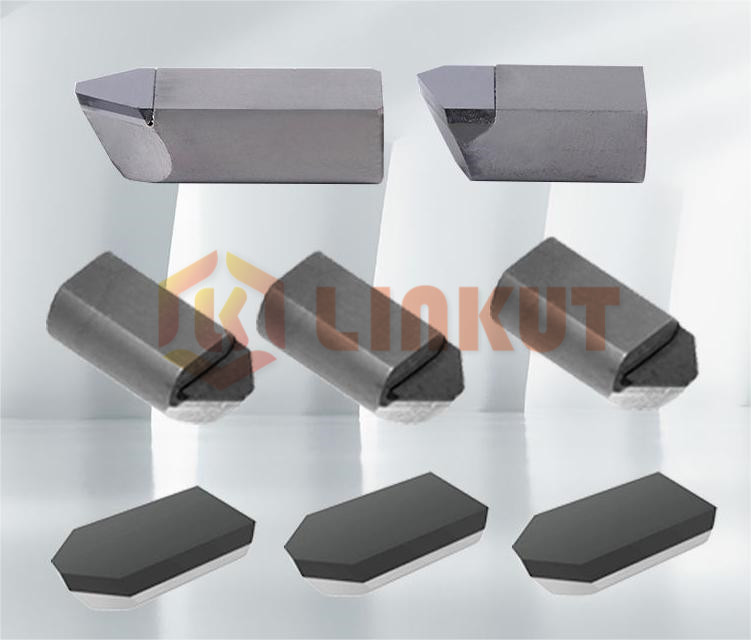

PCD Notching&Boring Tools for Tungsten Carbide Rolls

LINKUT provide Carbide notching tool and PCD notching tool for turning and milling HSS rolls and carbide rolls, which has the advantages of high processing efficiency and suitable for dry and wet cutting.

PCD notching tools have two structures:brzaed and full face, full face PCD notching tools are used for tools below 4mm, brazed PCD notching tools are larger than 5mm, and only the cutting edge is PCD, the base is cemented carbide.

Advantages of PCD boring tools:

High abrasive resistance and thermal conductivity;

Good surface finish;

Long service life. The service life is 20-30 times more than carbide boring tools.

Choice of cutting tools:

Notching and Boring Tools are mainly used for rib engraving of roll ring groove type.

According to the material and hardness of the processed rolls, the cutting tools are mainly divided into carbide notching tools, CBN grooving tools and PCD notching tools.

Carbide nothcing tools are mainly used for high-speed steel rolls with HSD<90;

When processing high-speed steel rolls with HSD>90, CBN notching tools are more suitable.

PCD rib cutters are suitable for higher hardness carbide rolls.

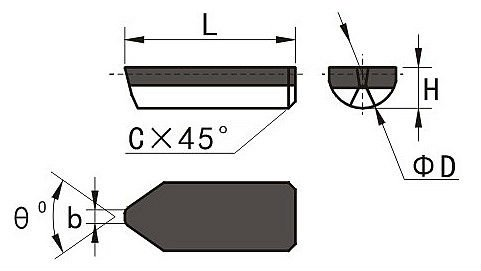

The specification of PCD boring and notching tools:

Grade | Dimension(mm) | ||||

ΦD | b | H | L | θ° | |

Φ2.5*0.5*5.2*80° | 2.5 | 0.5 | 1.6 | 5.2 | 80° |

Φ3*0.6*5.5*80° | 3.0 | 0.6 | 1.8 | 5.5 | 80° |

Φ3.2*0.6*6.2*85° | 3.2 | 0.6 | 1.8 | 6.2 | 85° |

Φ4*0.6*7.53*80° | 4.0 | 0.6 | 1.8 | 7.53 | 80° |

Φ4*0.7*7.83*70° | 4.0 | 0.7 | 2.3 | 7.83 | 70° |

Φ4*0.8*9.55*80° | 4.0 | 0.8 | 2.4 | 9.55 | 80° |

Φ4.5*0.9*10.7*80° | 4.5 | 0.9 | 2.75 | 10.7 | 80° |

Complete specifications, various specifications and models can be produced, customized production according to the customer's size.

Previous Article:The Successful Application of PCD Cutting Tools In Processing Resin Lenses

Next Article: PCD Grooving Tools Successfully Application in Automobile &Engineering Industries