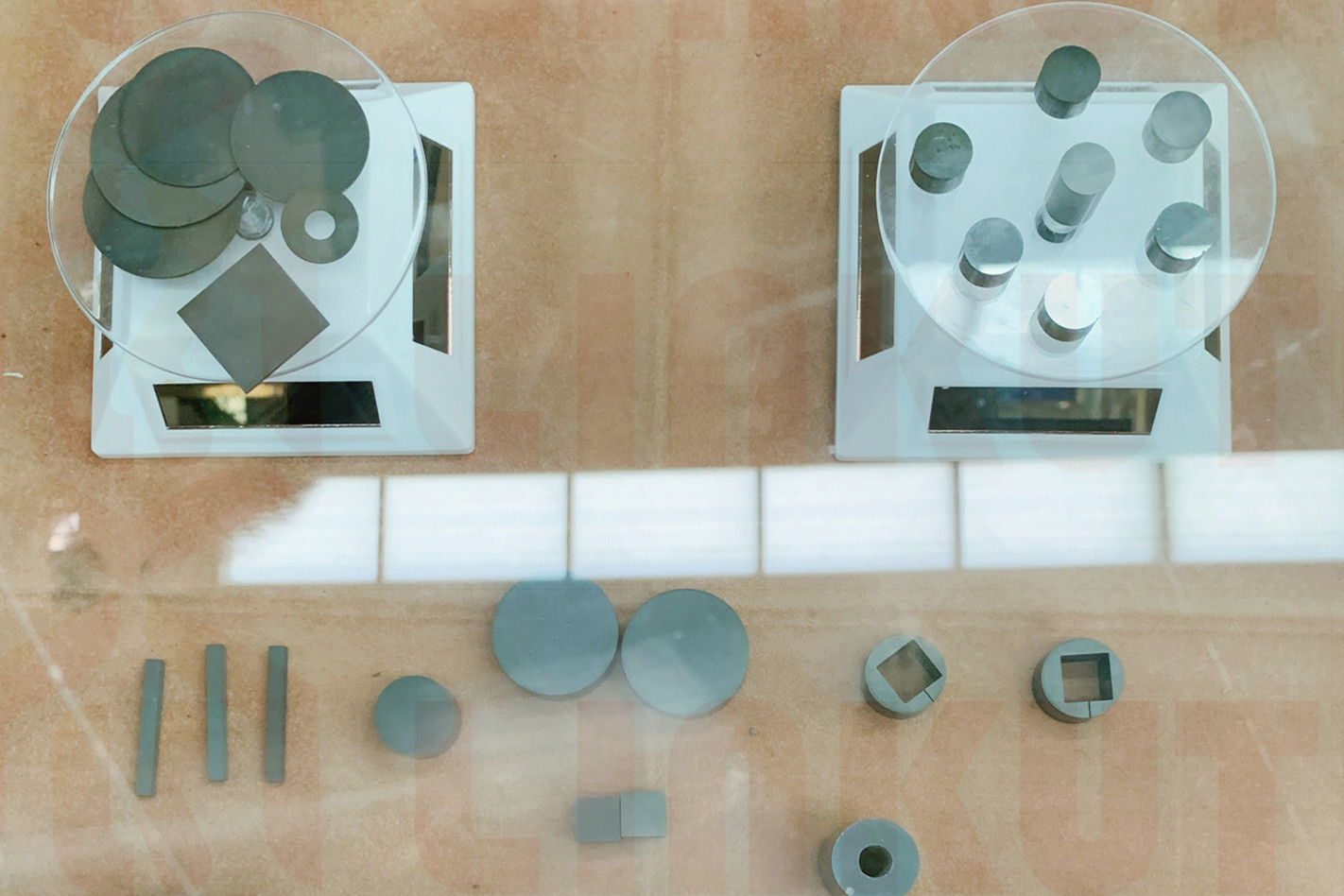

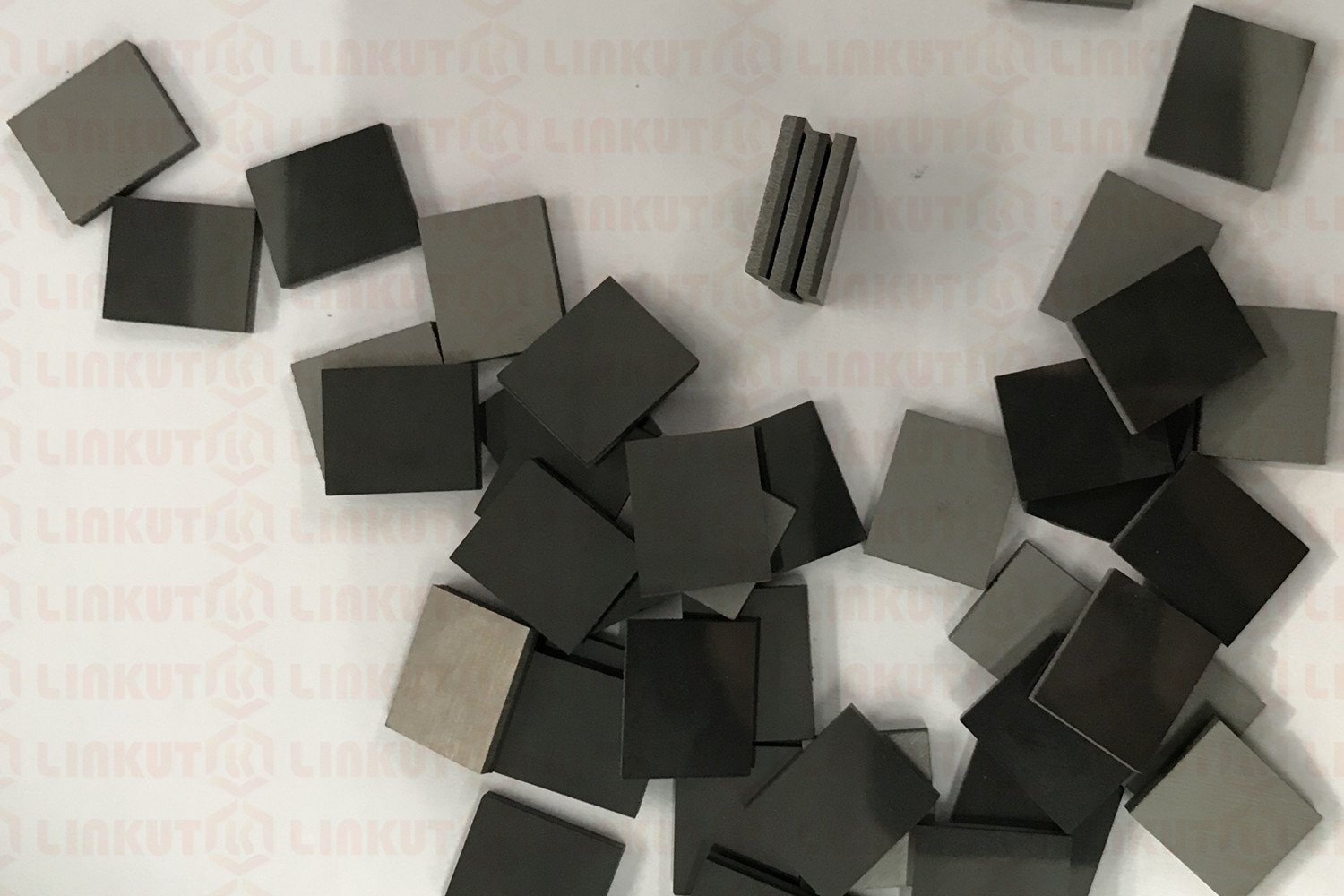

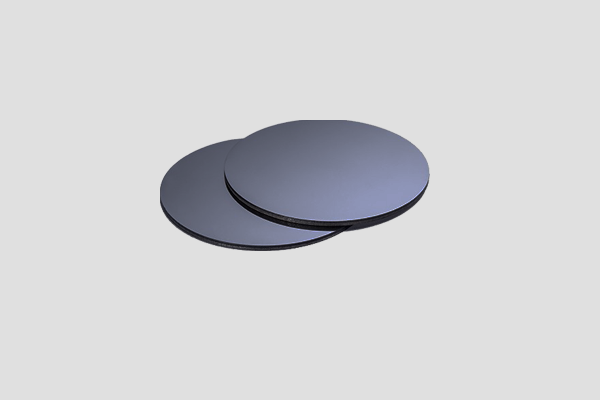

PCD Blanks

Features:

Cost effective;

Excellent wear resistance;

Longer tool life.

The PCD cutting tool blank (polycrystalline diamond) is composed of a polycrystalline diamond layer and a

cemented carbide substrate.

The selected diamond particles are sintered together with the hard alloy by an ultrahigh pressure high temperature process.

PCD inserts are used on diamond tools, saw blades, drills, and milling cutters to process workpieces such as cemented

carbide, PVC, and aluminum products. The application range of diamond tools is now expanding to many fields such as aviation,

aerospace, automotive, electronics, stone and so on.

The features of LINKUT PCD cutter:

Adopt independent formula technology, long service life;

High hardness, high compressive strength, surface smoothness , high thermal conductivity and good abrasion resistance;

Could obtain high machining accuracy and efficiency in high-speed cutting.

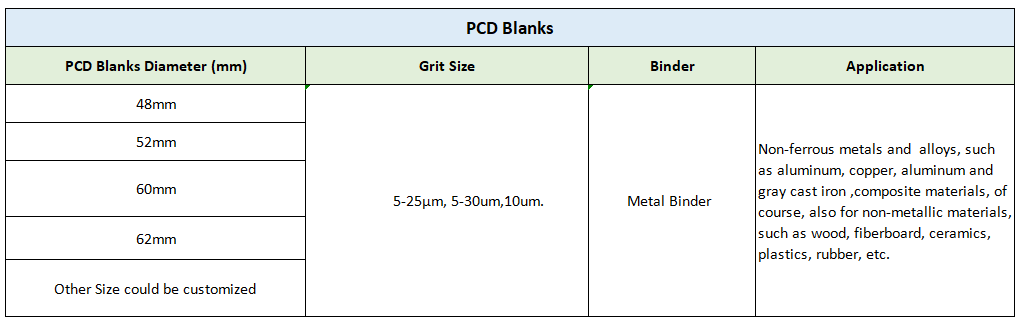

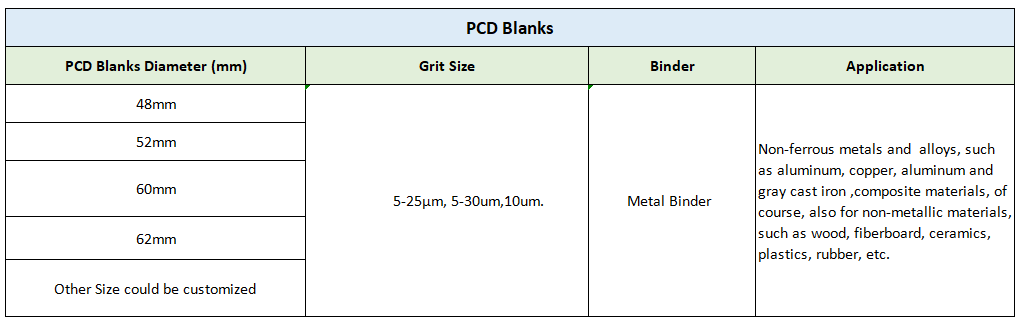

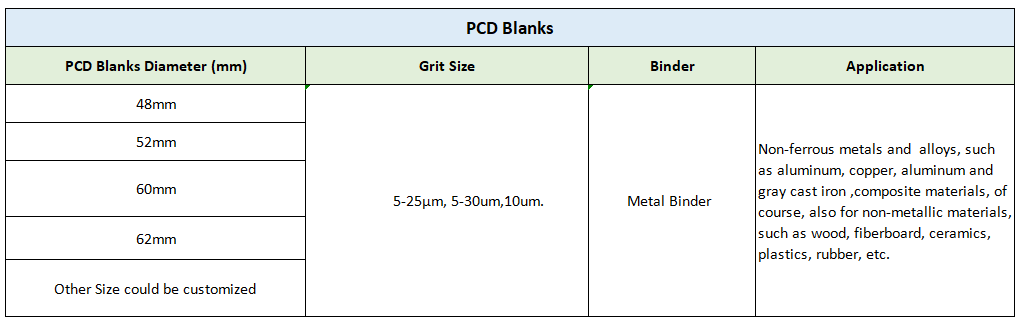

The PCD blanks are widely used in the polishing of non-ferrous metals and alloys, such as

aluminum, copper, aluminum / iron gray composite materials, and non-metallic materials such as

wood, chipboard, ceramics, plastics, rubber, etc.

-

EDM Cuttable Silicon Polycrystalline Dia

Details -

PCD Stone Cutting Cutters

Details -

PCD Blanks

Details -

PCD Milling Cutter

Details