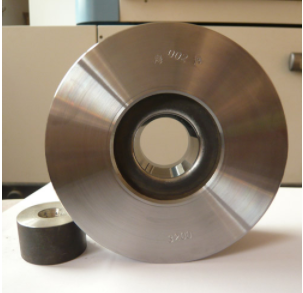

The Relationship Between Bearing and Drawing of Wire-Drawing Diamond Dies

The bearing diameter of the wire drawing diamond dies is determined according to the allowable tolerance of the wire and the elastic deformation of the wire during

drawing, and the life of the die is taken into account, and the negative tolerance dimension of the wire is usually selected.

The following requirements should be met when determining the length of the bearing: sufficient wear resistance, energy consumed during drawing, and the possibility

of breaking the wire. If the bearing is too long, the life of the wire drawing die can be increased, but at the same time, the friction, the heat generation and the energy

consumption are increased, and the wire diameter is easily reduced or the wire is broken. If the bearing is too short, the wire will be shaken and the bamboo shape will be

formed during drawing, and the inner hole of the drawing die will wear quickly, resulting in an oversize. In general, the larger the diameter of the drawn wire, the shorter the

length of the bearing.

Previous Article:CBN Cutting Tools for Hard Turning Bearing Steel

Next Article: LINKUT Mid-Autumn Holiday Information