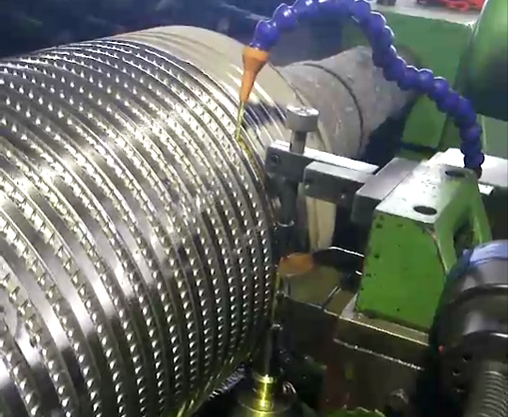

CBN Turning Inserts for HSS Roll and TC Roll Machining

Before we introduce the fit CBN turning inserts grades to the HSS and Tungsten carbide materials machining, we should know some knowledge for the

2 kinds of materials.

High-speed steel (HSS) is a tool steel with high hardness, high wear resistance and high heat resistance, also known as wind steel or front steel, which

means hardening even when cooled in air during quenching, and is very sharp. Also known as white steel.

High-speed steel is a complex alloy steel containing tungsten, molybdenum, chromium, vanadium, cobalt and other carbide forming elements. The total

amount of alloying elements is about 10 to 25%. It maintains high hardness under high heat cutting (about 500 ° C) and HRC can be above 60.

Tungsten steel (hard alloy) has a series of excellent properties such as high hardness, wear resistance, strength and toughness, heat resistance and

corrosion resistance, especially its high hardness and wear resistance, even at temperatures of 500 ° C. It remains essentially unchanged and still has

a high hardness at 1000 °C.

Tungsten steel, the main component is tungsten carbide and cobalt, which accounts for 99% of all components, 1% of other metals, so called tungsten

steel, also known as hard alloy, is considered to be the teeth of modern industry.

For the above two materials, LINKUT could provide the professional turning solutions for high speed steel rolls and carbide roll, such as our solid cbn

inserts grades IBN100 RNGN090300, IBN400 RCGX090700.

Previous Article:The Die Quality Factor-Diamond Wire Die Management

Next Article: CBN Cutting Tools for Hard Turning Bearing Steel