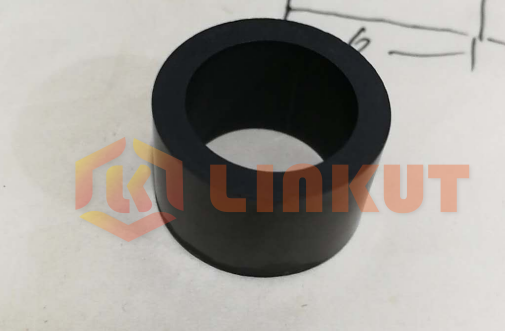

What is the Fit Hole for the Diamond Wire Drawing Die?

The fit hole is important for effectively improving the service life of diamond wire drawing die:

1. The intersection of the parts of the mold must be obvious, so that each part can fully play its role, avoiding the reduction of the length of the bearing part by the transition angle;

2. The longitudinal section of each part of the hole type must be straight, and the straight working cone has the smallest pulling force;

3. The bearing part must be straight and of reasonable length. The bearing part is too long, the friction of the wire is increased, and the wire is easily broken or broken after being pulled

out of the die hole. The bearing part is too short, and it is difficult to obtain a wire with stable shape, accurate size and good surface quality, and the die hole is also will wear out too badly.

4. Extend the height of the entrance part and the working zone so that the wire enters the middle section of the working hole of the die hole, and the wedge shape formed by the inlet taper

angle and the upper half of the working cone angle is used to establish a "wedge effect", and the surface of the wire material is formed denser and firmer. Lubricating film, reducing wear,

suitable for high speed drawing;

Previous Article:The Reasonable Choice of Diamond Tools Cutting Methods

Next Article: CBN Inserts for Brake Disc Machining with High Cutting Efficiency