PCBN Inserts Failure Mode for Turning Hardened Steel

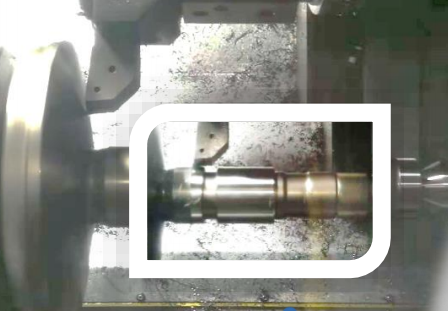

In actual machining, parts hard turning with PCBN inserts such as machined gear end faces, end faces with several oil holes, and spline shaft outer circles, which require

interrupted cutting, such as PCBN inserts for hardened (GCr15) bearing steel machining:

Compared with continuous cutting, the crater wear area of the rake face is much smaller during light interrupted machining process. This is because the tool is not always

in contact with the workpiece during interrupted cutting, the chips are broken, and the chips can be removed in time. most of the heat generated during cutting is carried away

by the chips. Therefore, the cutting heat accumulated near the cutting edge is less than the continuous cutting, resulting in the crater wear of the rake face is not being as wide

as continuous cutting. Compared with continuous and light interrupted cutting, the heavy interrupted cutting path is much less, so the crater wear of the rake face is not as deep

as the former two, and the area of the flank face is not bigger than the light intermittent.

Previous Article:The Impact Toughness of PCD Blanks

Next Article: Common Causes of Damage to PDC Drill Bits