The Structure and Function of the Diamond Wire Drawing Die Core

Diamond wire drawing dies are a very important consumable product for various metal wire manufacturers to draw wire.

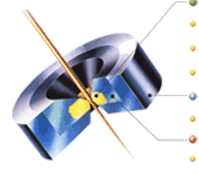

The structure and function of the wire drawing die core are as follows:

Entrance Part: which facilitates threading and prevents the wire from scratching the wire drawing die from the inlet direction;

Lubrication Part: through which the wire is easily brought into the lubricant;

Reduction Part: which is the main part of the die hole, the deformation of the wire process takes place here, reducing the original section to the required section size.

When the conical metal is drawn, the space occupied by the volume of the metal in the working area is a circular table, which is called a deformation zone. The cone

half angle α (also known as the mold hole half angle) in the working area is mainly used to determine the drawing force;

Bearing Part: is used to obtain the accurate size of the drawn steel wire;

Exit Part: is used to prevent the steel wire outlet from being unstable and scratch the surface of the wire.

Previous Article:CBN Inserts for High Efficiency Turning Brake Drum

Next Article: PCBN Inserts for Cylinder Liner Machining