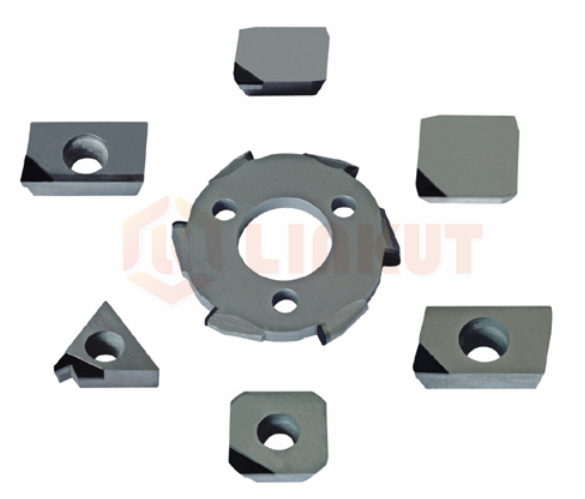

The Main Applications of CVD CNC Machine Inserts in Diamond Tools

Compared with PCD tools, CVD cnc machine inserts have lower surface roughness and better cutting edge; It can replace natural diamond tools in some fields.

PCD, PCBN and synthetic single crystal diamond are synthesized under high temperature and high pressure, while CVD diamond is synthesized under low pressure.

The Main Applications of CVD CNC lathe turning tools in Diamond Tools:

1) CVD tools are used for metal cutting

CVD diamond tools can be used to make turning tools, milling tools, planers, boring tools and other machining tools. Practice shows that CVD tools adopt correct

geometric angle and can be used as precision cutting tools for non-ferrous metals and superhard materials after fine grinding, such as motor tools for turning red

copper (also known as commutator tools). CVD tools can achieve the effect of turning instead of grinding and machining to mirror roughness, and their cost is much

lower than that of natural diamond single crystal diamond tools.

2) CVD is used for non-metallic processing

CVD is also popular in woodworking tools because of its high wear resistance. CVD is an ideal tool material for the processing of hard and brittle materials such as

stone, glass fiber, carbon composites and organic composites.

3) High precision tools

CVD diamond tools have been widely used in superfinishing, finishing, semi finishing and continuous cutting. Their wear resistance is 2 ~ 10 times higher than PCD

tools, and their performance price ratio is better than other diamond tools.

LINKUT is specialied in supplying PCD PCBN CVD tooling solution for your machining.

Previous Article:CBN Ball End Milling Cutter for Milling High Hardness Steel Die

Next Article: Application of High Performance PCD Indexable Tools