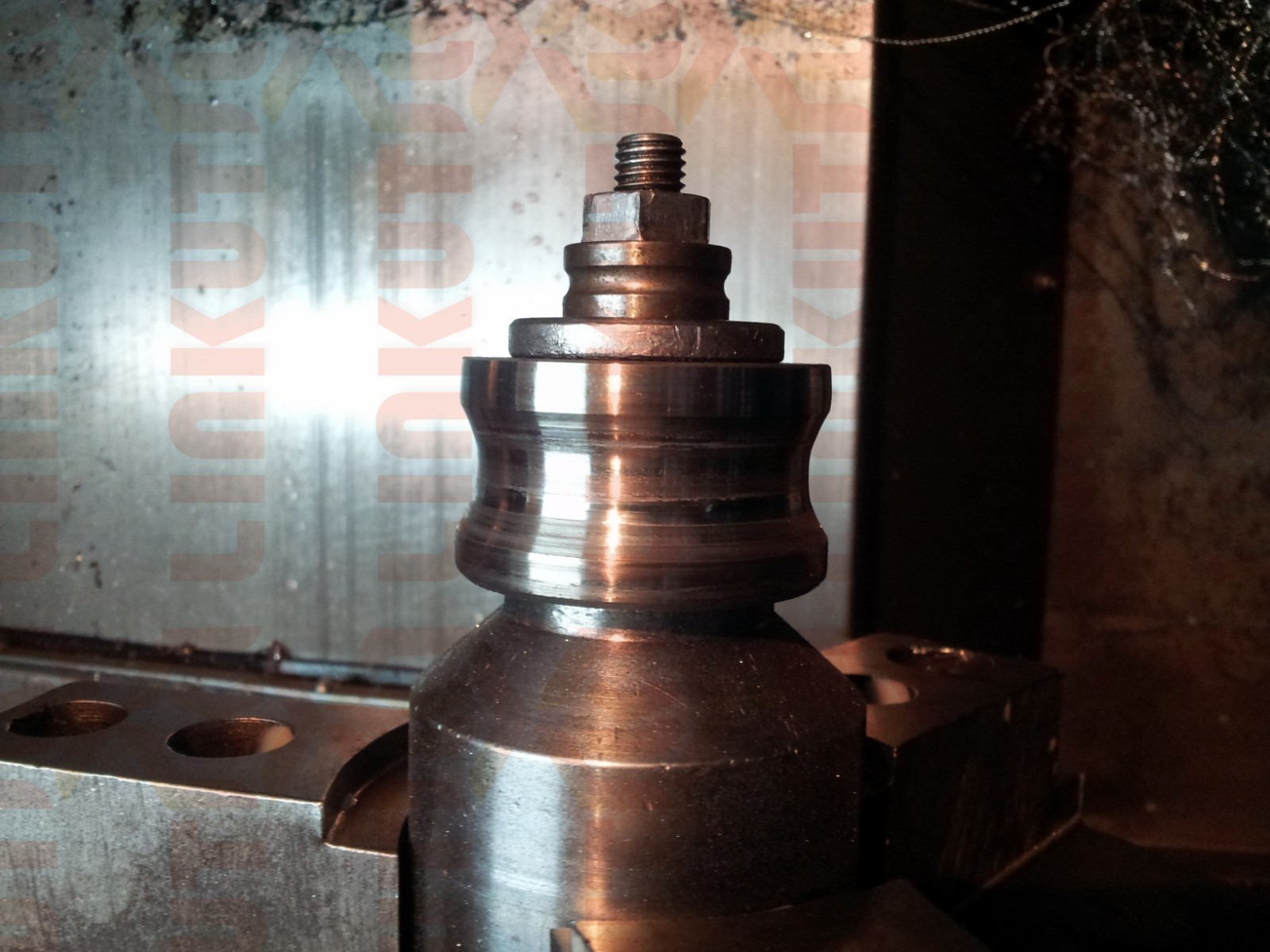

LINKUT-Professional Solution Provider For Roll Machining and Repairing

Common materials of Rolls are: chilled cast iron, alloy cast iron, high-speed steel, forged steel, powder metallurgy, etc., which are large parts, usually with higher hardness and

larger cutting allowance. LINKUT has rich solutions in machining Rolls and repairing. Common cutting tools of pcbn models are RNGN, RCGX, SNGN.

Roll cutting tool requirements:

1) High hardness, good wear resistance, high temperature resistance

The hardness of the roll is generally above HSD55. Our IBN100 and IBN400 use a unique production process to ensure the wear resistance, thermal stability and high temperature

red hardness of the blade. It can easily process workpieces above HSD55 and is not prone to rapid blade wear or collapse caused by high temperature. Blade phenomenon. Tool

life is 3-5 times longer than ceramic tools.

2) Strong impact resistance

Casting rolls, especially the surface of large rolls, will inevitably have casting defects (such as hard spots, sand inclusions, porosity, etc.), conventional tools are prone to chipping,

and the impact resistance is poor. Our CBN inserts can be continuously-intermittently processed without chipping or cutting, and the durability is more than ten times higher than

ceramic tools. They can replace imported tools, and the inserts are grooved to make the clamping more secure.

3) Large depth of cut

The roll blank has a large margin on one side, the conventional tool has a small cutting depth, and the efficiency is low. The maximum cutting depth of our overall blade roughing rolls

can reach 1/3 of the cutting edge, which has a very high blank removal rate; multiple cutting edges can improve blade utilization.

4) High efficiency

CBN can still maintain high hardness at a high temperature of 1200 degrees. This characteristic determines that a higher cutting speed can be selected when using PCBN tools. For

example, LINKUT IBN100 pcbn tool turning HSD78 high-nickel-chromium cast iron rolls; the single-side cutting depth can reach about 7mm; the feed rate of cutting is 0.8-1.2mm/R.

Previous Article:The Influence of Drawing Process and Die on Mechanical Properties of Steel Wire

Next Article: CBN PCD Tools for Cutting Cemented Carbide Precision Parts