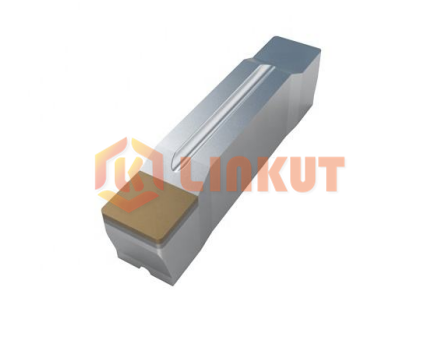

Application of PCD Grooving Cutter in Automobile Industry

LINKUT PCD grooving cutter has been very excellent applied in automobile, air conditioning compressor and other industries.

Due to the extremely high precision and surface roughness required for the workpiece groove, LINKUT PCD grooving cutter with superhard and high wear resistance, which not only improves the processing accuracy of the workpiece, saves processing costs, but also improves production efficiency.

PCD notching tool is mainly used for cutting various aluminum, copper and other non-ferrous metal outer circular grooves, end grooves and inner hole grooves.

LINKUT PCD grooving cutter product features:

1) The main material of PCD grooving cutter is PCD (Artificial polycrystalline diamond). PCD not only has superior properties of diamond, such as high hardness, high wear resistance, high thermal conductivity, low friction coefficient, low thermal expansion coefficient, but also has good strength and toughness of cemented carbide.

2) The service life of PCD blade is 10-20 times that of cemented carbide. It has an ultra-long service life in aluminum alloy and copper alloy processing. It has excellent processing performance in non-alloy materials, such as ceramics, stone, rubber, graphite, stone, etc.

3) It is very suitable for product finishing, and the processing effect can reach the mirror effect. It can replace grinding with turning and milling.

Previous Article:Application of PCD Micro-drill in The Chip Industry

Next Article: Application of PCD Wheel Hub Turning Tools