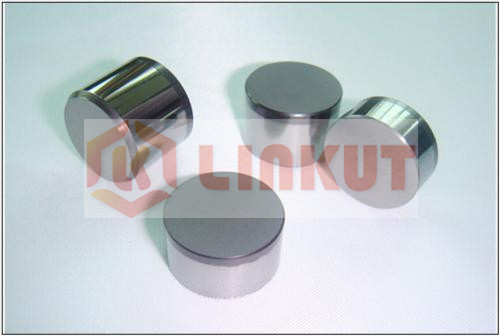

LINKUT High Wear Resistance PDC Cutter

Polycrystalline diamond composite have been widely used in geological exploration, coal field mining, and oil drilling. The main technical indicators for measuring the quality

of LINKUT PDC insert cutter are heat resistance, wear resistance and impact resistance.

Abrasion resistance refers to the ability of PDC's polycrystalline diamond layer to resist wear during cutting, drilling, dressing, etc. The factors that affect the abrasion resistance

of PDC are:

1) The level of abrasion resistance is related to the PDC process;

2) Under the same manufacturing process, it depends on the diamond particle size of the raw material for the synthesis of PDC. Different diamond sizes have different abrasion

resistance. In general, the finer the diamond size, the higher the abrasion resistance.

3) The abrasion resistance of PDC is related to the content of the binder.

Such as LINKUT 1308, 1613 pdc blank inserts are very popular in the markets due to its excellent wear resistance.

Previous Article:Wire Drawing Die Insert Blank-The core component of PCD Drawing Die

Next Article: Basic maintenance of PDC Cutter Drilling Tool